Top 10 Tips for Choosing the Best TIG Welding Machine for Your Needs

Choosing the right TIG welding machine is a critical decision that can significantly impact the quality of your welding projects. According to a recent industry report by the Welding Equipment Manufacturers Association, the market for welding equipment, including TIG machines, is expected to grow at a compound annual growth rate (CAGR) of 5.4% from 2021 to 2028. This growth is driven by increasing industrial applications and the rising demand for high-precision welding processes across various sectors, including aerospace, automotive, and construction.

When selecting a TIG welding machine, it's essential to consider several factors such as power requirements, portability, and ease of use. The right machine not only enhances productivity but also ensures safety and precision in your welding tasks. Studies indicate that over 70% of welders cite equipment performance as a primary factor influencing their job satisfaction, highlighting the importance of making an informed choice. By understanding your specific needs and the capabilities of different machines, you can make a selection that aligns perfectly with your welding applications and skill level.

Understanding TIG Welding: A Brief Overview

TIG welding, or Tungsten Inert Gas welding, is a process widely respected for its precision and versatility, making it ideal for a range of materials including stainless steel, aluminum, and copper alloys. Unlike other welding techniques, TIG welding uses a non-consumable tungsten electrode to produce the weld, requiring a filler material that is manually fed into the weld pool. This method allows for greater control of the welding process, resulting in cleaner welds and a superior aesthetic finish.

According to the American Welding Society (AWS), the TIG welding market is projected to grow significantly in the coming years, driven by increased demand in various industries such as automotive, aerospace, and construction. The precision associated with TIG welding is essential in sectors where integrity and visual appeal of welds are paramount. Reports indicate that about 24% of welders prefer TIG welding for its ability to handle thin materials effectively, which underscores the technique's value in specialized applications. Additionally, with advancements in inverter technology, modern TIG welding machines have become more energy-efficient and user-friendly, appealing to both novice and experienced welders alike.

Key Features to Consider When Selecting a TIG Welding Machine

When selecting a TIG welding machine, understanding the essential features can significantly enhance your welding experience and outcomes. One critical aspect is the output range of the machine. According to industry reports, a versatile TIG welding machine should offer an amperage range of at least 5 to 300 amps, allowing for both thin and thick material welding. This flexibility is crucial for varying tasks, from intricate automotive repairs to heavy industrial projects.

Another key feature to consider is the type of power supply. Machines can operate on DC, AC, or a combination of both. A study from the Welding Research Council indicates that 80% of TIG welding applications utilize AC power for aluminum and magnesium due to its ability to remove oxides from these metals, ensuring better fusion. Hence, assessing the power supply type is vital for achieving optimal results in your specific projects.

Additionally, portability can greatly affect your decision. A lightweight machine with a sturdy design can be advantageous, especially for fieldwork. Many professionals emphasize the importance of ease of transport, as this feature aids in access to remote job sites. For avid welders, investing in a machine that balances weight, durability, and power settings is essential for maintaining productivity without compromising on quality.

Top 10 Tips for Choosing the Best TIG Welding Machine for Your Needs

| Feature | Description | Importance Level |

|---|---|---|

| Power Source | Consider whether you need an AC or DC power source depending on the materials you are welding. | High |

| Weld Thickness | Determine the maximum thickness of the materials you will work with to select a suitable amp range. | Medium |

| Portability | If you need to move your machine frequently, consider its weight and design. | Medium |

| User-Friendly Controls | Look for machines with easy-to-use settings and displays for precision control. | High |

| Duty Cycle | Check the duty cycle to ensure the machine can handle your welding needs without overheating. | High |

| Price | Set a budget that aligns with the features you need to avoid overspending. | Medium |

| Accessories Included | Consider what accessories come with the machine, such as torches, cables, and regulators. | Low |

| Warranty | A solid warranty can indicate the manufacturer's confidence in their product. | High |

| Brand Reputation | Research customer reviews and brand reliability to ensure quality performance. | Medium |

| Safety Features | Ensure the machine includes safety features to protect you during the welding process. | High |

Assessing Power Requirements for Your Specific Projects

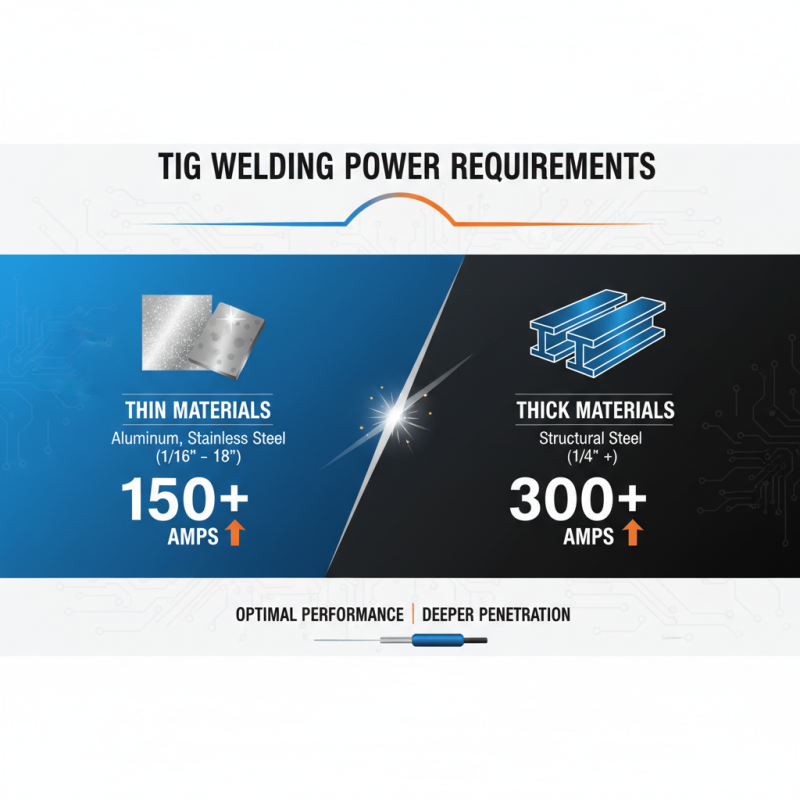

When selecting a TIG welding machine, understanding power requirements is crucial for ensuring optimal performance in your specific projects. The power output of a welding machine directly influences its ability to handle various materials and thicknesses. According to industry standards, for welding thin materials like aluminum or stainless steel, a machine with a minimum output of 150 amps is typically recommended. In contrast, heavier structural welding may require machines capable of delivering up to 300 amps or more, depending on the thickness of the materials involved. This ensures deeper penetration and a stronger weld.

Additionally, it is important to consider the type of power source your project will demand. Most TIG welding machines operate on either single-phase or three-phase power. A study by the American Welding Society highlights that three-phase machines are preferable for industrial applications due to their higher efficiency and ability to maintain a stable arc. Meanwhile, smaller workshops or hobbyists may benefit from single-phase machines, which are often easier to source and more versatile for less demanding projects. Overall, accurately assessing power requirements based on the materials and thicknesses you intend to work with will guide you to a TIG welding machine that meets your needs effectively.

Portability and Size: Choosing the Right Machine for Your Workspace

When selecting a TIG welding machine, one of the most critical factors to consider is the portability and size of the equipment. A compact and lightweight machine is ideal for those who work in various locations or have limited space in their workshop. Smaller TIG welding machines are easier to transport, allowing welders to move them to job sites without hassle. Additionally, the size of the machine often contributes to the ease of storage, making it essential to choose a model that fits comfortably within your workspace without taking up excess room.

Moreover, the workspace layout should guide your choice of a TIG welding machine. For tight or confined environments, a machine with a smaller footprint can facilitate efficient workflow without compromising performance. If your projects require frequent repositioning or adjustments, a portable machine with ergonomic features—such as comfortable handles and a well-balanced design—enhances usability, ultimately improving your welding experience.

Balancing size and portability with the power and features you need is key to finding the best TIG welder for your specific welding projects.

Budgeting: Finding Quality within Your Price Range

When budgeting for a TIG welding machine, it’s crucial to strike a balance between quality and affordability. According to a recent industry analysis from MarketsandMarkets, the global welding equipment market is projected to reach $24.17 billion by 2027, driven largely by advances in technology and increasing demand in various sectors such as automotive and construction. This growth signals that there are numerous options available across different price ranges, making it essential to identify a machine that meets your needs without overspending.

Investing in a quality TIG welding machine typically involves an upfront cost that can vary significantly. Entry-level models can start around $300, but may lack the performance and features necessary for more demanding projects. In contrast, mid-range machines priced between $800 and $2,000 often provide enhanced control and versatility, catering to both hobbyists and professionals. A report from IBISWorld indicates that effective budgeting should also take into account the total cost of ownership, including maintenance and the cost of consumables, to ensure long-term value. Therefore, evaluating your specific welding requirements alongside your budget is vital for making an informed decision that doesn’t compromise on performance.

Related Posts

-

Why Invest in a TIG Welding Machine for Your Next Project?

-

Top 10 Benefits of Gas Tungsten Arc Welding You Need to Know

-

10 Essential Tips for Choosing the Right MIG and TIG Welder for Your Projects

-

Discover the Best Handheld Laser Welders for Top Efficiency in 2025

-

Top 10 Benefits of Hand Held Laser Welding Machines You Need to Know

-

Exploring the Advantages of Hand Held Laser Welding Machines: Efficiency and Precision Unleashed