2025 Top Laser Marking Innovations for Enhanced Precision and Efficiency

In the rapidly evolving landscape of manufacturing and product branding, laser marking technology has emerged as a cornerstone for enhancing precision and efficiency. According to a recent report by MarketsandMarkets, the global laser marking market is projected to grow from $2.2 billion in 2020 to $3.5 billion by 2025, reflecting a remarkable compound annual growth rate (CAGR) of 9.3%. This growth is driven not only by increasing demand for high-quality marking solutions but also by the continuous advancements in laser technologies, which are providing manufacturers with innovative tools to improve their processes.

Dr. Emily Tran, a leading expert in laser applications at the Institute of Laser Engineering, emphasizes the critical role of these innovations, stating, “The future of laser marking relies on integrating smarter systems that enhance productivity without compromising on quality.” As we approach 2025, it becomes increasingly vital for industries to stay abreast of the latest advancements in laser marking techniques. This article will showcase the top five innovations that are set to revolutionize the sector, highlighting their potential to deliver unmatched precision and efficiency in marking applications.

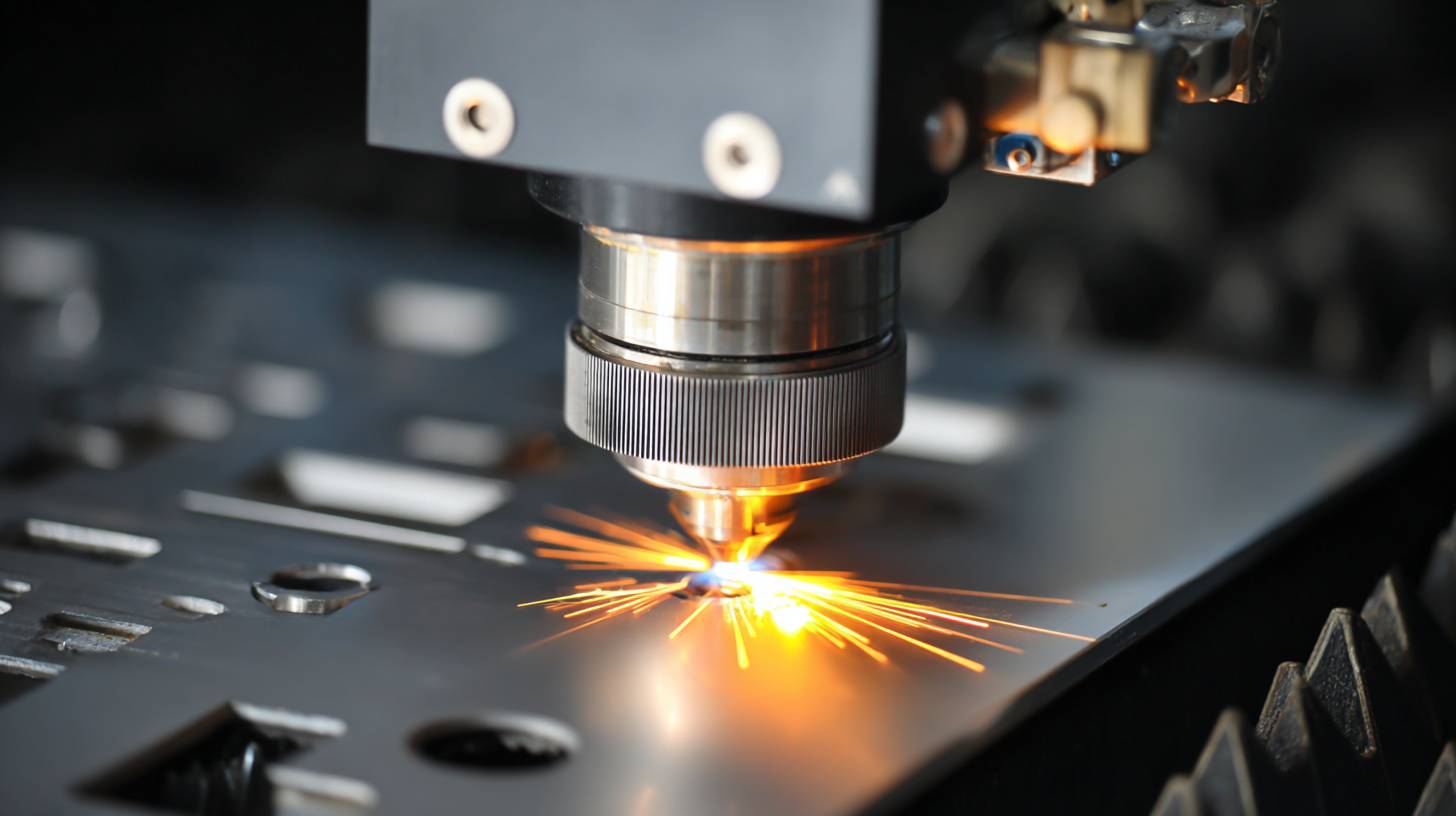

Emerging Laser Technologies Revolutionizing Marking Precision

In an era where precision, durability, and efficiency are paramount in manufacturing, emerging laser technologies are set to revolutionize marking precision. Advanced laser systems are leveraging higher frequency capabilities and improved beam quality, which enable finer detail and enhanced control over marking processes. With innovations like fiber lasers and diode lasers, manufacturers can achieve robust and permanent markings on various materials while minimizing thermal distortion and improving overall productivity.

Additionally, the integration of artificial intelligence and machine learning into laser marking systems is reshaping the landscape of precision manufacturing. These technologies allow for real-time adjustments and adaptive marking techniques, ensuring that each marking is optimized for the specific characteristics of the material being processed. This level of sophistication not only improves accuracy but also accelerates production speeds, making laser marking a crucial asset in industries ranging from automotive to electronics. As these laser technologies continue to evolve, they promise to streamline operations and enhance the quality of products globally.

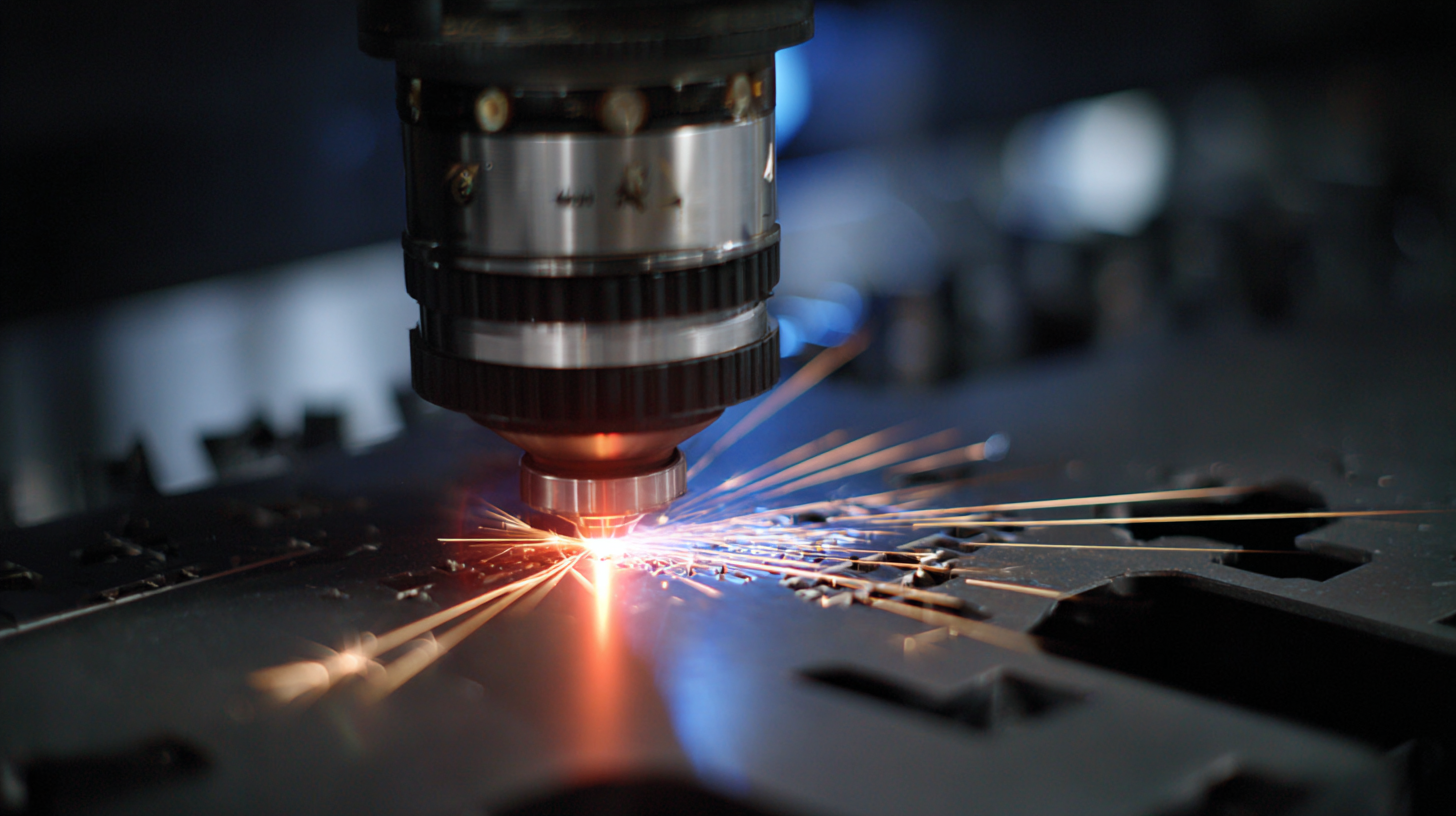

AI-Driven Laser Marking Systems for Real-Time Adaptability

The integration of artificial intelligence into laser marking systems marks a significant shift towards enhanced precision and efficiency in manufacturing. AI-driven technologies are enabling real-time adaptability in laser marking processes, allowing for adjustments that cater to the complexity of different materials and design requirements. This enhances overall production quality, minimizes waste, and streamlines operations by optimizing marking parameters on the fly.

Moreover, various startups in the laser technology sector are at the forefront of this innovation, contributing to a vibrant ecosystem that leverages AI for advanced manufacturing solutions. These companies focus on developing cutting-edge laser marking systems that not only improve accuracy but also respond dynamically to operational demands. As AI continues to reshape the landscape of industrial processes, businesses that adopt these technologies will likely gain a competitive edge, harnessing the full potential of data-driven models to drive efficiency and product customization in laser marking applications.

Sustainable Materials and Their Impact on Laser Marking Efficiency

The integration of sustainable materials has become increasingly significant in the field of laser marking, drastically impacting efficiency and overall output quality. According to a 2023 report by MarketsandMarkets, the global market for eco-friendly laser marking materials is projected to grow at a compound annual growth rate (CAGR) of 10% from 2023 to 2028. This shift not only underscores the demand for sustainable practices but also highlights the advancements in laser technologies that favor these materials. When utilizing biodegradable plastics and recycled metals, manufacturers can achieve a marked reduction in waste, while simultaneously enhancing the precision of their laser marking processes.

Recent studies indicate that leveraging sustainable materials can improve the speed of laser marking operations by up to 15%. This increase in efficiency is attributed to the optimized interaction between the laser and the eco-friendly substrates, which often display lower thermal conductivity. Furthermore, laser systems that are compatible with these materials require less energy to operate, aligning with industry trends towards sustainability and cost-effectiveness. As more companies embrace these innovations, the synergy between laser marking technology and sustainable materials not only leads to operational advantages but also promotes environmental stewardship within the manufacturing sector.

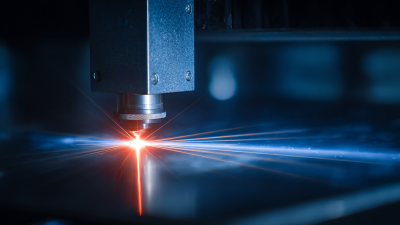

Integration of IoT in Laser Marking for Enhanced Workflow Management

The integration of IoT in laser marking represents a significant shift towards enhanced workflow management across various industries. By connecting laser marking systems with the Internet of Things, businesses can achieve real-time data exchange, enabling greater precision and efficiency in marking processes. This smart connectivity allows for the monitoring of equipment performance, predictive maintenance, and enhanced production planning. As a result, manufacturers can minimize downtime and reduce waste, ultimately leading to improved productivity and cost-effectiveness.

Moreover, the recent trends in laser technology highlight the emergence of advanced applications, including the utilization of robotic precision in surgeries and the development of novel laser wireless power transmission systems. These innovations not only enhance operational capabilities but also drive a new wave of startups focused on leveraging laser technology for diverse applications. With the laser marking industry evolving rapidly, businesses must stay informed about these trends and adapt to maintain a competitive edge in the market.

User-Friendly Interfaces: Bridging the Gap Between Technology and Users

In the realm of laser marking innovations, the development of user-friendly interfaces is reshaping how both seasoned professionals and newcomers interact with cutting-edge technology. These interfaces are designed with the user in mind, emphasizing simplicity and accessibility. By integrating intuitive design elements and streamlined workflows, manufacturers are bridging the gap between complex laser marking systems and the operators who use them. This accessibility allows users with varying levels of expertise to maximize the potential of laser marking technology without extensive training.

Moreover, the evolution of user interfaces contributes significantly to operational efficiency. Enhanced graphics, real-time monitoring, and customizable settings enable users to make informed decisions quickly, further reducing the potential for errors. As laser marking technology continues to advance, the focus on user-friendly design will be crucial in facilitating smoother interactions and ultimately improving productivity. By prioritizing the needs of users, these innovations not only enhance precision in marking applications but also create a more engaging and less daunting experience in utilizing advanced technology.

Related Posts

-

Understanding the Benefits of Laser Marking Technology in Modern Manufacturing

-

Unveiling the Future: How Laser Welders Revolutionize Modern Manufacturing Techniques

-

Mastering Tig Welding Aluminum Techniques for Stronger Joints and Improved Performance in Every Project

-

Revolutionizing Manufacturing: How Welding Automation Increases Efficiency by 30% and Reduces Costs

-

Unlocking Precision and Efficiency with Handheld Laser Welders in Modern Manufacturing

-

Exploring the Advantages of Hand Held Laser Welding Machines: Efficiency and Precision Unleashed