Top Features of the Best Laser Welding Guns for Precision Metalwork

In the realm of precision metalwork, the use of advanced tools is essential for achieving flawless results. Among these tools, the laser welding gun stands out as a game-changer for professionals and hobbyists alike. With its ability to concentrate energy precisely, a laser welding gun allows for clean, strong, and efficient joins in a variety of metal types. This technology has revolutionized the welding industry, offering significant advantages over traditional welding methods, such as reduced heat distortion and improved control over weld parameters.

As the demand for high-quality metalwork increases, understanding the top features of laser welding guns becomes crucial for selecting the right tool for specific applications. From power output and beam quality to ergonomics and safety features, the best laser welding guns are designed with functionality and user experience in mind. These features ensure that operators can achieve superior results while maintaining their comfort and safety during the welding process. In this article, we will explore the key characteristics that define the best laser welding guns, providing insights into why they are indispensable in precision metalwork.

Key Considerations in Selecting Laser Welding Guns for Metalwork

When selecting laser welding guns for precision metalwork, several key considerations play a pivotal role in ensuring optimal performance and desired results. One of the foremost factors is the laser power output, which can significantly affect the weld quality and speed. Reports indicate that higher power lasers, typically ranging from 1000W to 6000W, can produce finer welds at faster speeds, thereby enhancing productivity in industrial applications. This is particularly important for projects requiring intricate details and minimal thermal input to avoid warping and distortion of the materials being welded.

Additionally, the focus diameter of the laser beam is crucial in determining the precision of the welding process. A smaller focus diameter allows for tighter welds and greater control over the heat affected zone, which is vital in applications involving thin materials. For instance, data from industry studies suggest that welds produced with a spot diameter under 0.5 mm are generally more effective for delicate tasks, minimizing the risk of material damage. Moreover, considering the duty cycle and cooling system of the laser welding gun is essential to ensure longevity and consistent performance during prolonged use. As the demand for high-quality metalwork continues to increase, choosing the right features in a laser welding gun can make a significant difference in welding accuracy and efficiency.

Top Features of the Best Laser Welding Guns for Precision Metalwork

| Feature | Description | Importance |

|---|---|---|

| Wavelength | Commonly ranges from 800 to 1000 nm which is ideal for most metals. | Critical for absorption efficiency in various materials. |

| Power Output | Ranges from 200W to 2000W; determines the types of materials that can be welded. | Higher power allows for thicker materials. |

| Cooling System | Water-cooled systems prevent overheating during intense operations. | Essential for prolonged usage without thermal failures. |

| Beam Quality | Measured by the M2 factor; lower values indicate a more focused beam. | Important for achieving fine welds and minimizing distortion. |

| Portability | Lightweight designs facilitate ease of use and transport. | Enhances usability in various work environments. |

| Control Features | Advanced user interface providing settings for speed, power, and pulse frequency. | Allows for customization to match specific project requirements. |

| Safety Features | Includes protective lenses and emergency shutoff controls. | Essential for operator safety and compliance with regulations. |

Types of Laser Welding Technologies Used in Precision Applications

Laser welding technologies have advanced significantly, becoming essential in precision metalworking applications. Among the most prominent types are Continuous Wave (CW) lasers and Pulsed lasers. Continuous Wave lasers provide a steady beam of light, ideal for processes requiring consistent energy input, such as welding thicker materials or achieving deep penetration welds. Their efficiency in high productivity environments makes them a favorite for manufacturers looking to enhance throughput while maintaining high-quality joins.

Pulsed lasers, on the other hand, deliver bursts of energy, allowing for greater control over the amount of heat applied to the material. This feature is particularly advantageous for delicate components where excessive heat can lead to warping or other damage. Pulsed laser welding is widely used in industries such as electronics and jewelry, where precision is critical. By adjusting the pulse duration and energy, operators can tailor the welding process to specific materials and thicknesses, ensuring strong, reliable welds that meet stringent quality standards.

These technologies enable a versatile approach to precision welding, facilitating a broad range of applications from automotive to aerospace, where the demands for performance and reliability are paramount. As industries evolve, the continued refinement of these laser welding techniques will provide even greater opportunities for innovation in metal fabrication.

Top Features of the Best Laser Welding Guns

Essential Features for High-Quality Laser Welding Guns

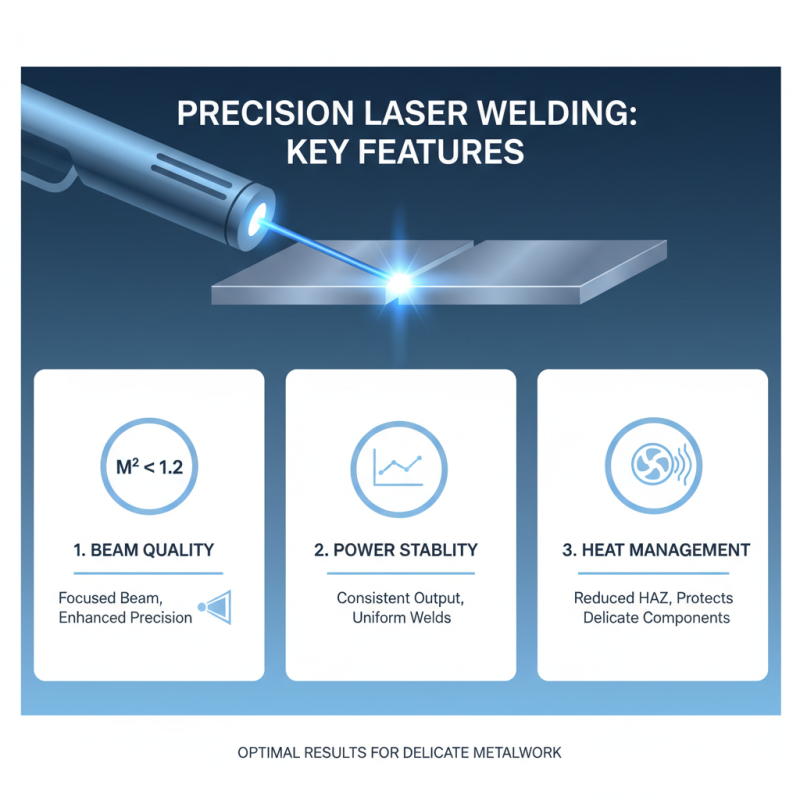

When it comes to precision metalwork, the choice of a laser welding gun can significantly impact the quality and efficiency of the work. Essential features of high-quality laser welding guns play a crucial role in achieving optimal results. One primary feature to consider is beam quality, often measured by the M² factor. High-performance laser welding guns typically exhibit an M² value less than 1.2, resulting in a focused beam that enhances precision and reduces heat-affected zones, crucial for delicate components.

Another essential feature is power variability. Laser welding guns with adjustable power settings allow operators to tailor the output based on material thickness and type. A recent industry report indicates that machines with power modulation capabilities can improve penetration depth and welding speed by up to 40%, offering more versatility in applications ranging from automotive to aerospace manufacturing. Additionally, an ergonomic design is vital for operator comfort and control, minimizing fatigue during prolonged use which is often noted as a common issue in metal fabrication environments.

Furthermore, the incorporation of advanced cooling systems is becoming increasingly important for sustained performance during high-demand tasks. Data suggests that laser welding guns equipped with effective cooling mechanisms can maintain optimal operational temperatures, thereby extending the lifespan of the equipment and reducing downtime due to overheating. By focusing on these essential features, professionals in the field can ensure they select laser welding guns that not only meet but exceed their precision metalworking needs.

Safety Features and Practices for Using Laser Welding Equipment

When working with laser welding equipment, safety is paramount. According to industry research, workplace accidents involving laser tools can lead to severe injuries, emphasizing the need for rigorous safety practices. A survey conducted by the American Welding Society indicates that nearly 40% of welding professionals have experienced at least one unsafe occurrence related to inadequate protective measures. Therefore, understanding the integral safety features of laser welding guns and implementing best practices can significantly reduce risks.

One essential safety feature to consider in laser welding guns is the inclusion of protective eyewear that meets the necessary optical density ratings. This protects the welder's eyes from harmful laser reflections and exposure. Additionally, many modern laser welding systems are equipped with advanced safety interlocks that prevent the machine from operating when safety guards are not properly in place, as highlighted in a report by the Optical Society. Ensuring that workers are trained in these safety features is crucial for maintaining a safe working environment.

Proper ventilation is another critical component of laser welding safety. The American National Standards Institute recommends that workplaces utilizing laser welding equipment have adequate exhaust systems in place to mitigate the accumulation of harmful fumes and particulates. According to a study by the National Institute for Occupational Safety and Health, poorly ventilated areas can result in higher rates of respiratory issues among welders. Implementing these ventilation systems alongside routine safety audits can help promote a culture of safety and awareness among laser welding operators.

Maintenance Tips for Longevity of Laser Welding Guns

Maintaining laser welding guns is crucial for ensuring their longevity and optimal performance in precision metalwork.

Regular cleaning is a foundational maintenance practice. After each use, it’s important to wipe down the exterior and inspect the optical components for any residue or debris that may have accumulated. Dust and contaminants can interfere with the laser's effectiveness, leading to subpar welds or even damage to the equipment.

Using appropriate cleaning solutions and soft cloths can help preserve the integrity of the components while avoiding scratches.

Additionally, routine checks on electrical connections and cooling systems are essential. Overheating can significantly shorten the lifespan of a laser welding gun, so ensuring that the cooling systems are functioning properly will prevent malfunctions. Moreover, checking for any signs of wear or damage on cables and connectors can prevent unexpected breakdowns. Keeping a detailed maintenance log can also help identify patterns or recurring issues, allowing for more efficient troubleshooting and timely replacements of worn parts.

By following these maintenance tips, users can maximize the functionality and durability of their laser welding guns, thereby enhancing their performance in precision metalwork.

Related Posts

-

Top 10 Benefits of Hand Held Laser Welding Machines You Need to Know

-

Unlocking the Future: How Micro Welders Are Revolutionizing Precision Manufacturing

-

2025 Top Benefits of Using Argon Gas for TIG Welding You Should Know

-

Discover the Best Handheld Laser Welders for Top Efficiency in 2025

-

2025 Top Laser Marking Innovations for Enhanced Precision and Efficiency

-

Understanding the Benefits of Fiber Laser Welding Machines: A Comprehensive Guide for Modern Fabrication