2025 Top Benefits of Using Argon Gas for TIG Welding You Should Know

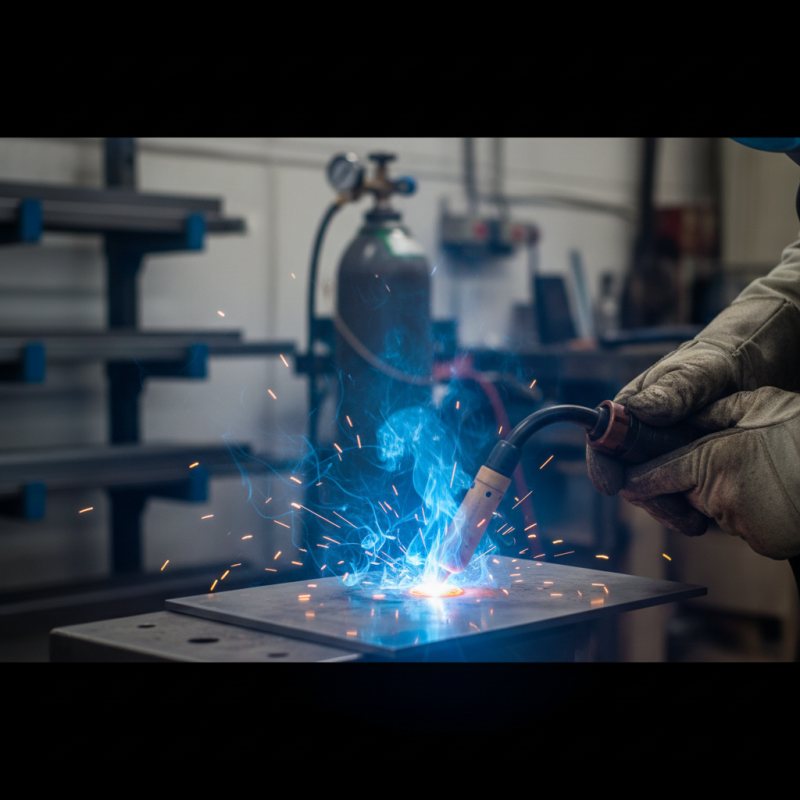

TIG welding, or Tungsten Inert Gas welding, is renowned for its precision and versatility in joining various metals. One of the critical elements that contribute to the success of this welding process is the use of argon gas. Argon gas for TIG welding offers a plethora of advantages, making it a preferred choice among welders, whether they are professionals or enthusiasts. Its inert properties create a stable and shielded environment for the weld pool, preventing contamination and ensuring high-quality welds.

As the demand for efficient and clean welding processes continues to rise, understanding the benefits of using argon gas for TIG welding becomes increasingly vital. From enhancing the aesthetic appeal of welds to improving arc stability and penetration, argon gas plays a significant role in achieving optimal welding outcomes. This article explores the top benefits associated with argon gas for TIG welding, shedding light on why this noble gas is an indispensable component in modern welding practices. By delving into these advantages, we aim to equip welders with the knowledge necessary to harness the full potential of argon gas, ultimately leading to superior welding results.

Benefits of Argon Gas in TIG Welding: An Overview

Argon gas has become the preferred shielding gas for Tungsten Inert Gas (TIG) welding, owing to its various advantages that enhance the quality and efficiency of the welding process. One of the primary benefits of using argon is its inert nature, which prevents oxidation and contamination of the weld area. According to the American Welding Society, the use of argon can significantly improve arc stability and reduce the likelihood of defects, resulting in cleaner and stronger welds. This is particularly crucial when working with sensitive materials such as aluminum and stainless steel, where impurities can lead to serious structural weaknesses.

Additionally, argon's density makes it particularly effective at minimizing the effects of atmospheric contamination. The gas's heavier-than-air properties mean that it effectively blankets the weld pool, providing a stable and controlled environment that reduces the risk of porosity. A study conducted by the Welding Research Council noted that argon shielding led to a reduction in porosity levels by up to 90% in certain welding applications. These characteristics not only enhance the mechanical properties of the welded joints but can also lead to significant cost savings by decreasing the need for rework and increasing production efficiency. With over 60% of TIG welding operations utilizing argon in various industrial applications, its benefits are clear, making it an indispensable asset in the welding industry.

Enhanced Weld Quality with Argon: Key Advantages Explained

Argon gas has emerged as a preferred shielding gas in Tungsten Inert Gas (TIG) welding, offering several key advantages that significantly enhance weld quality. One of the primary benefits of using argon is its inert nature, which plays a crucial role in preventing oxidation and contamination of the weld pool. According to a report by the American Welding Society, the use of argon can lead to a reduction in defects such as porosity by up to 25%, thereby ensuring cleaner and more reliable welds.

Moreover, argon provides excellent arc stability, which is vital for producing high-quality welds in various welding positions. A study conducted by the Welding Research Council indicates that welders using argon as a shielding gas experience improved arc performance, resulting in higher penetration and reduced spatter. This enhanced control during the welding process not only leads to superior weld appearance but also contributes to the overall structural integrity of the welded joint.

In addition to these qualities, argon allows for greater versatility in welding a range of materials, from stainless steel to aluminum. The ability to achieve consistent results across different metals is supported by data from industry surveys, which indicate that approximately 60% of TIG welders prefer argon due to its adaptability and the superior quality of welds it produces. Thus, the benefits of using argon gas clearly position it as a cornerstone in modern welding practices, particularly for those seeking to achieve enhanced weld quality.

Cost Efficiency of Argon Gas for TIG Welding Applications

Argon gas is increasingly recognized for its cost efficiency in TIG welding applications. One of the primary advantages of using argon is its ability to create a stable and consistent arc, which enhances the quality of the weld while significantly reducing the amount of wasted filler material. By providing a cleaner shielding environment, argon minimizes contamination, leading to fewer defects and rework costs, ultimately delivering more savings in time and resources.

Tip: To maximize cost efficiency, ensure the correct flow rate of argon gas for your specific application. A flow rate that is too high can result in a waste of gas, while a flow rate that is too low may lead to poor shielding and compromised weld quality.

Furthermore, argon gas tends to be more affordable compared to other shielding gases, especially when considering bulk purchasing options. This cost-effectiveness can further enhance the profitability of welding operations. Investing in argon not only supports high-quality welds but also helps maintain a budget-friendly approach to welding projects.

Tip: Consider using argon gas in combination with a high-quality TIG welding machine to optimize performance and cost savings, as the combination can lead to a reduction in downtime and maintenance costs.

Safety and Environmental Considerations of Using Argon Gas

Using argon gas for TIG welding offers several safety and environmental benefits that make it a preferred choice among welders. Firstly, argon is an inert gas, meaning it does not react with molten metal. This characteristic significantly reduces the risks of explosive reactions or harmful byproducts during the welding process. As a non-toxic gas, argon presents minimal health risks to workers when proper ventilation is maintained, making it a safer alternative compared to other gases that may produce harmful fumes.

Moreover, argon's clean and efficient properties contribute positively to environmental considerations. It helps in reducing the emission of pollutants during welding, leading to a cleaner working environment. The use of argon minimizes the generation of hazardous waste and byproducts, promoting a more sustainable approach to welding practices. In an era where environmental regulations are becoming stricter, opting for argon gas is not only a matter of personal or workplace safety but also aligns with broader efforts to protect the planet and adhere to eco-friendly standards.

Comparative Analysis: Argon vs. Other Shielding Gases in TIG Welding

When it comes to TIG welding, the choice of shielding gas plays a crucial role in determining the quality and efficiency of the weld. Argon gas stands out as the preferred option for many welders due to its unique properties. One of the primary advantages of argon is its inert nature, which prevents oxidation and contamination during the welding process. This characteristic is particularly beneficial when welding non-ferrous metals, as it ensures a cleaner and stronger weld joint compared to other shielding gases like CO2 or helium.

In a comparative analysis, argon gas offers several benefits over alternatives such as CO2 and mixed gas combinations. While mixed gases can provide better heat control and penetration in some cases, they often introduce more variables that can affect the weld quality. Argon's ability to produce a stable arc and maintain a consistent heat profile allows for greater precision and control during welding. Furthermore, unlike CO2, argon doesn’t lead to increased spatter and provides a more aesthetically pleasing finish, making it the superior choice for applications where appearance is crucial. Overall, while each gas has its own merits, argon consistently proves to be the most effective shielding gas for achieving high-quality TIG welds.

Related Posts

-

10 Essential Tips for Choosing the Right MIG and TIG Welder for Your Projects

-

Understanding the Benefits of Laser Marking Technology in Modern Manufacturing

-

2025 Top 5 Argon Gas Products for Superior TIG Welding Performance

-

Top 10 Tips for Choosing the Best TIG Welding Machine for Your Needs

-

Why Invest in a TIG Welding Machine for Your Next Project?

-

Discover the Best Handheld Laser Welders for Top Efficiency in 2025