10 Tips for Choosing the Best TIG Welder for Your Projects?

Choosing the right TIG welder can greatly influence your project outcomes. With many options available, making a decision can feel overwhelming. TIG welding is favored for its precision and quality. However, not all welders are created equal.

When selecting a TIG welder, consider the material you'll work with. Aluminum, stainless steel, and mild steel each require different settings. Pay attention to the power supply options. A balance between portability and power can be crucial.

Sometimes, less expensive machines may lack vital features. You may find a perfect fit. Yet, the question remains: does it meet your needs? Remember, investing in a quality TIG welder pays off in the long run. Consider your projects carefully and avoid the pressure to rush your decision.

Importance of TIG Welding in Various Industries

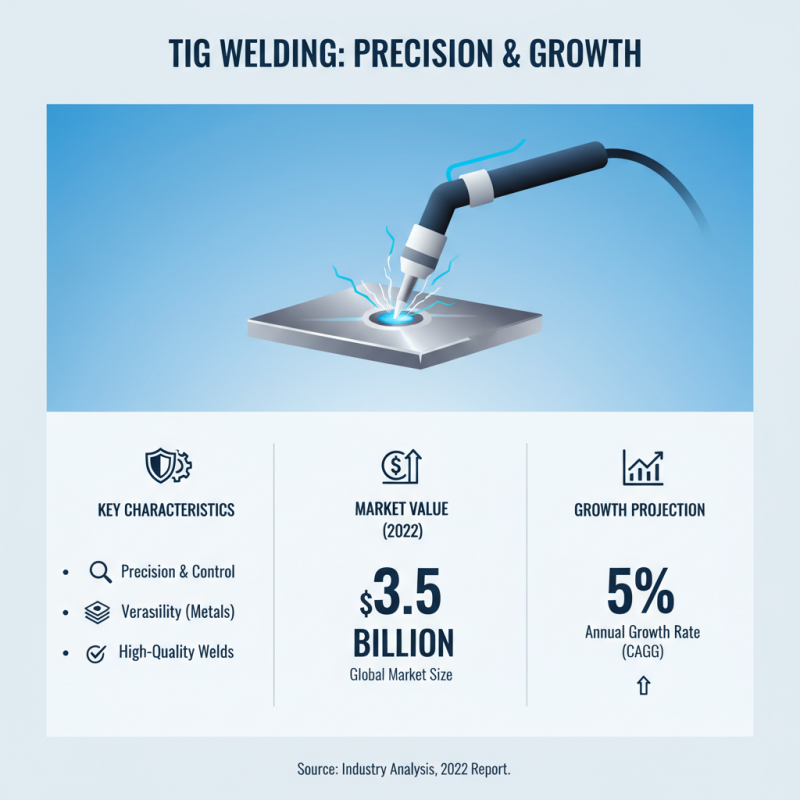

TIG welding, known for its precision, plays a crucial role in many industries. From aerospace to automotive, its versatility is unmatched. In 2022, the global TIG welding market was valued at approximately $3.5 billion, with projections indicating a steady growth rate of 5% annually. This indicates its rising importance in modern manufacturing.

Choosing the right TIG welder is critical. One key tip involves understanding your project's material type. Different materials require specific welding techniques and settings. It's important to consider the thickness of the materials you will be working with. Heavier materials need higher amperage for penetration, while thinner metals need delicate control.

The importance of TIG welding also extends to the medical industry. For example, high-quality welds are essential for manufacturing surgical instruments. Poor welds can introduce contaminants, jeopardizing patient safety. Attention to detail is paramount in such applications.

When selecting a TIG welder, be cautious about purchasing a model based solely on price. The features and performance should suit your project requirements. Assessing the duty cycle is also crucial. A welder with a low duty cycle may not handle long projects efficiently. Always consider how often you'll use the welder. Reflecting on these factors will guide you to a suitable choice.

Key Specifications to Consider When Choosing a TIG Welder

When selecting a TIG welder, understanding key specifications is crucial. One of the primary factors is the amperage range. Most reputable data sources suggest an ideal range of 10 to 300 amps for general use. This versatility allows for welding various materials, from thin sheets to thicker metals. Having a welder with a broader amperage range can help in diverse project requirements.

Another important consideration is the duty cycle. Industry reports indicate that a duty cycle above 60% is generally preferred for continuous work. This means that a welder can operate for longer periods without overheating. A lower duty cycle may lead to interruptions during your project, affecting both productivity and final results. It's essential to choose a machine that meets long-term project demands, rather than just a short-term solution.

Lastly, consider the type of torch and gas flow control. A torch with adjustable gas flow enhances precision. The right setup can greatly influence the quality of the weld. Improper gas flow can result in contamination and poor bonding. Thus, investing in a proper setup is crucial, even if it seems like an extra expense. Remember, each weld counts on the final outcome of your project.

10 Tips for Choosing the Best TIG Welder for Your Projects

Comparing AC vs. DC TIG Welders and Their Applications

When it comes to TIG welding, the choice between AC and DC is crucial. AC (Alternating Current) is often favored for aluminum and magnesium. It offers better cleaning action, which removes oxide from these metals. However, AC may not provide that strong penetration needed for thicker materials. It's essential to consider the specific projects you will undertake.

On the other hand, DC (Direct Current) is ideal for welding steel and stainless steel. It provides a steady arc and deep penetration, making it suitable for a variety of applications. However, DC might struggle with aluminum, leading to less effective welds. Some users find themselves frustrated when trying to use DC on materials better suited for AC. It's a reminder that understanding these differences can save time and materials.

Each current type has its strengths and weaknesses, which can impact your work. Choosing the wrong type can lead to unsatisfactory results. Reflecting on past projects, one might realize that the current used didn’t align with the material. This is a common oversight that can affect the overall quality of your welding. Understanding both AC and DC capabilities ensures you choose the right welder for your specific applications.

Understanding Duty Cycle Ratings for TIG Welders: What to Look For

When selecting a TIG welder, duty cycle ratings are crucial. The duty cycle indicates how long a welder can run before needing a break. It is usually expressed as a percentage. A welder with a 60% duty cycle can operate for six minutes within a ten-minute period. This rating affects your welding project efficiency.

Consider the materials you will work with. Thicker metals require higher amperage and longer welding times. A lower duty cycle may limit your capabilities. If you often tackle large projects, look for a welder with a higher duty cycle. During your search, ensure you balance power and duty cycle based on your needs.

When assessing models, check for amperage settings. More variability allows for versatile applications. Pay attention to the cooling system as well. A robust system can enhance duty cycles significantly. Opt for features that improve your overall experience. Many first-time buyers overlook these factors. Take the time to evaluate before making a choice.

Cost vs. Quality: Evaluating TIG Welder Options for Budget Projects

When selecting a TIG welder, the balance between cost and quality is crucial. Many options exist, but they vary significantly in price and performance. A budget welder might save you money initially, but consider the long-term costs. Cheaper machines often require more frequent repairs and replacement parts. This can lead to frustration in the middle of a project.

Quality welders typically offer better features and durability. They can handle various materials effectively. Investing in a reliable tool can improve your craftsmanship. However, always assess your specific project needs. Not every task requires the highest-end model. Sometimes, a mid-range option is sufficient.

Think about what you need. Are you working on aluminum or stainless steel? Will you be using it for professional work or personal projects? These details matter. Reflect on your budget versus the essential features you need. Don’t get sidetracked by flashy options. Often, less is more when it comes to getting the job done right.

10 Tips for Choosing the Best TIG Welder for Your Projects

| Feature | Importance | Budget Option | Quality Option |

|---|---|---|---|

| Input Power | High | 110V | 220V |

| TIG Torch Type | Medium | Air-Cooled | Water-Cooled |

| Weight | Medium | Portable | Stable |

| Welding Thickness | High | ≤ 1/8" | ≥ 1/4" |

| Duty Cycle | High | 20% | 60% |

| Price Range | High | $300 - $500 | $800+ |

Related Posts

-

10 Essential Tips for Choosing the Right MIG and TIG Welder for Your Projects

-

Why Invest in a TIG Welding Machine for Your Next Project?

-

How to Choose the Best Tig Welder for Your Welding Projects

-

Top 10 Handheld Laser Welding Machines for Efficient Metal Joining

-

Best Fiber Laser Welder Options for Precision and Efficiency in 2023

-

Unlocking the Future: How Micro Welders Are Revolutionizing Precision Manufacturing