The Ultimate Guide to Tig Welding Gas Types and Their Uses

TIG welding gas plays a vital role in achieving quality welds. The type of gas you choose can significantly influence the outcome of your project. In the world of TIG welding, the right gas selection is imperative.

Common options include argon and helium. Each gas offers unique benefits depending on the materials and applications involved. Argon is often favored for its stability, especially with stainless steel and aluminum. However, some welders prefer helium for thicker materials due to its higher heat capacity.

It's essential to understand how these gases affect the welding process. Choosing the wrong gas can lead to porosity, weak joints, or even project failures. As you dive into this guide, reflect on your experiences. What has worked for you? What hasn’t? Embracing both successes and failures can lead to improved techniques. Understanding the nuances of TIG welding gas is crucial for any welder looking to enhance their craft.

Understanding TIG Welding: An Overview of the Process

TIG welding, or tungsten inert gas welding, is a precise and versatile process. It uses a non-consumable tungsten electrode to produce the weld. The welder maintains a shield of inert gas, protecting the weld area from contaminants. This makes it ideal for thin materials and intricate designs.

The process requires skill and focus. The welder must control the heat, travel speed, and filler material. Each of these elements influences the quality of the weld. It's not as easy as it seems. Many new welders struggle with the steady hand needed for the arc. The art of TIG welding demands practice and patience.

Understanding the gas types used in TIG welding is vital. Argon is the most common choice, but helium and mixtures are also options. Each gas affects the weld bead differently. The welder must choose wisely based on the material and position. It's a constant learning curve. Awareness of how gas affects the process will lead to better results.

Key Types of Gases Used in TIG Welding

TIG welding relies heavily on gas selection. The primary gas types used are

argon, helium, and mixtures of both.

Argon is the most common choice. It is inert and highly effective at stabilizing the arc. According to the

American Welding Society, argon is used in 80% of TIG welding applications. It delivers a clean, precise weld without contamination.

Helium serves a different purpose. It offers higher heat input and faster welding speeds. This is crucial for thicker materials.

However, it can be more difficult to control. An industry report indicates that using helium can improve penetration in

aluminum and stainless steel.

This makes it popular for demanding projects.

Mixed gases, such as argon and helium, combine the benefits of both. They enhance arc stability while increasing heat. However, the choice can be complex.

Welders must consider the material and position. Some argue that over-reliance on gas mixtures may lead to inconsistent results.

This highlights the importance of experience and adaptability in TIG welding techniques.

Properties and Benefits of Argon as a TIG Welding Gas

Argon is widely recognized as the primary shielding gas for TIG welding. It offers several advantages that enhance weld quality. According to a report by the American Welding Society, argon provides excellent coverage and reduces contamination. It creates a more stable arc and improves overall penetration. This is crucial, especially when welding thin materials where precision is vital.

With an ionization potential of around 15.76 eV, argon requires less energy to create a welding arc. This leads to better control and less heat distortion in the materials being welded. In a study conducted by the Welding Institute, welding with argon produced fewer defects compared to other gases. However, it has limitations. For example, using argon alone is not ideal for all alloys. It may not provide the best results with reactive metals.

While argon is effective, it may not be enough for specific situations. Adding small amounts of hydrogen can improve arc stability for stainless steel. But too much can lead to porosity issues. These factors show that gas choice is not simple. Welders must consider the material and the desired outcome. Balancing the benefits and potential drawbacks of argon is essential for quality welding.

When to Use Helium in TIG Welding Applications

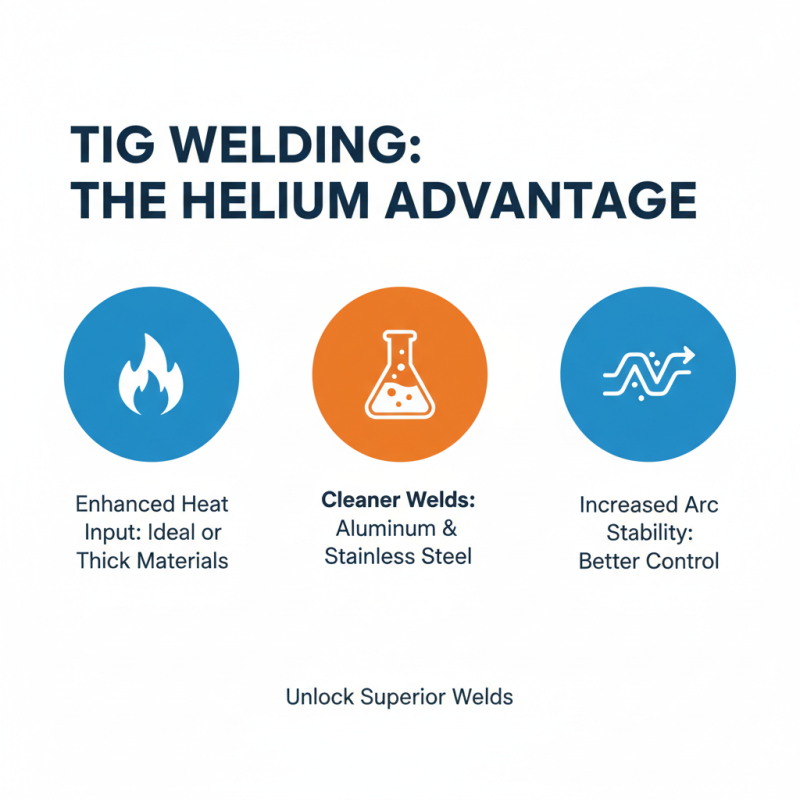

In TIG welding, choosing the right gas is crucial. Helium is often overlooked but can be beneficial in certain applications. It enhances heat input, making it ideal for thick materials. When welding aluminum or stainless steel, using helium can produce a cleaner weld. The increased arc stability allows for better control.

However, helium is more expensive than argon. This can be a challenge for cost-sensitive projects. Be mindful of the budget when considering helium. In some cases, a mixture of argon and helium works best. It retains the advantages of helium while being more economical.

Tips: Always experiment with gas mixtures in small projects. This helps you find the best settings without wasting materials. Monitoring weld quality is essential; adjust your gas blend based on the results. Practice makes perfect. Don't hesitate to refine your technique over time.

Combining Gases: Enhancing TIG Welding Performance with Mixtures

When it comes to TIG welding, the gas mixture used can greatly enhance performance. Combining gases can create a more stable arc, improve bead appearance, and reduce contamination. A popular mixture is pure argon with a small percentage of hydrogen. This blend can speed up the heating process, which is beneficial for thin materials.

Tip: Experiment with different gas mixtures. It’s important to find the right balance for your specific project. Sometimes, a little change can lead to a big improvement.

Another effective mix involves argon and helium. The addition of helium increases heat input, making it easier to weld thicker materials. However, keep in mind that it might also cause more spatter. Finding a comfortable balance is crucial.

Tip: Monitor the weld pool closely. If you notice excessive spatter, consider adjusting your gas mixture. Reflecting on your results can lead to better techniques and outcomes.

The Ultimate Guide to TIG Welding Gas Types and Their Uses

Related Posts

-

Top Features of the Best Laser Welding Guns for Precision Metalwork

-

2025 Guide: How to Choose the Best TIG Welding Machine for Your Needs

-

Understanding the Benefits of Fiber Laser Welding Machines: A Comprehensive Guide for Modern Fabrication

-

2025 Top Benefits of Using Argon Gas for TIG Welding You Should Know

-

How to Choose the Best Laser Marking Systems for Your Business Needs

-

Discover the Best Handheld Laser Welders for Top Efficiency in 2025