What is a Micro Welder and How Does it Work?

A micro welder is a specialized tool designed to fuse small parts together. It works by using high heat generated from a focused arc. According to Dr. Emily Jensen, a leading expert in micro welding technology, “Precision is key in micro welding; even the smallest misalignment can lead to failure.”

This statement emphasizes the importance of accuracy in this field. Micro welders are incredibly useful in various industries, from electronics to jewelry making. They allow craftsmen to perform delicate tasks that traditional welding cannot achieve. However, mastering the use of a micro welder presents challenges.

Improper settings or techniques can result in a weak bond. Components may overheat or become distorted during the welding process. Every operator must hone their skills to achieve the desired results. These challenges highlight the need for continuous learning and improvement in micro welding practices.

What is a Micro Welder?

A micro welder is a specialized tool used for intricate welding tasks. It is essential in industries like electronics and jewelry-making. This equipment joins small and delicate parts that would be difficult to weld using traditional methods. The precision it offers is unmatched, allowing for high-quality results in tiny components.

Micro welders utilize concentrated heat sources. They create strong and lasting bonds between small surfaces. The process often involves using lasers or electrical arcs. Laser welding is popular for its accuracy. It minimizes the risk of damage to surrounding areas. Users can work with materials such as gold, silver, and even thin metals. The welder essentially makes tiny welds that are barely visible.

Despite its advantages, using a micro welder requires skill. It demands a steady hand and patience. New users might struggle at first, missing spots or overheating materials. Experimentation is key to mastering this tool. Mistakes can lead to wasted materials and time. Yet, each attempt improves technique. This journey brings satisfaction in creating detailed work. The micro welder opens doors for creativity in small-scale projects.

The History and Development of Micro Welding

Micro welding has evolved significantly since its inception. Initially, the process was rudimentary, primarily conducted using manual techniques. Early micro welders relied on simple heat sources and basic tools. As technology advanced, the need for precision in welding grew. This prompted the development of specialized equipment, geared towards smaller components.

Modern micro welders use laser technology for increased accuracy. This allows welds in tight spaces and on delicate materials. Almost every industry employs micro welding today. From electronics to jewelry, precision is paramount. However, challenges remain. Workers must handle tiny parts with care. A misstep can ruin an entire batch.

Tip: Always maintain a clean work area to avoid contamination. This is crucial for achieving strong welds. Also, invest in high-quality tools. Quality impacts the final results significantly. Even small flaws can lead to failures. Reflecting on past mistakes is vital for mastering micro welding. Through practice, one can improve techniques and avoid repeating errors.

Micro Welding Applications Over the Years

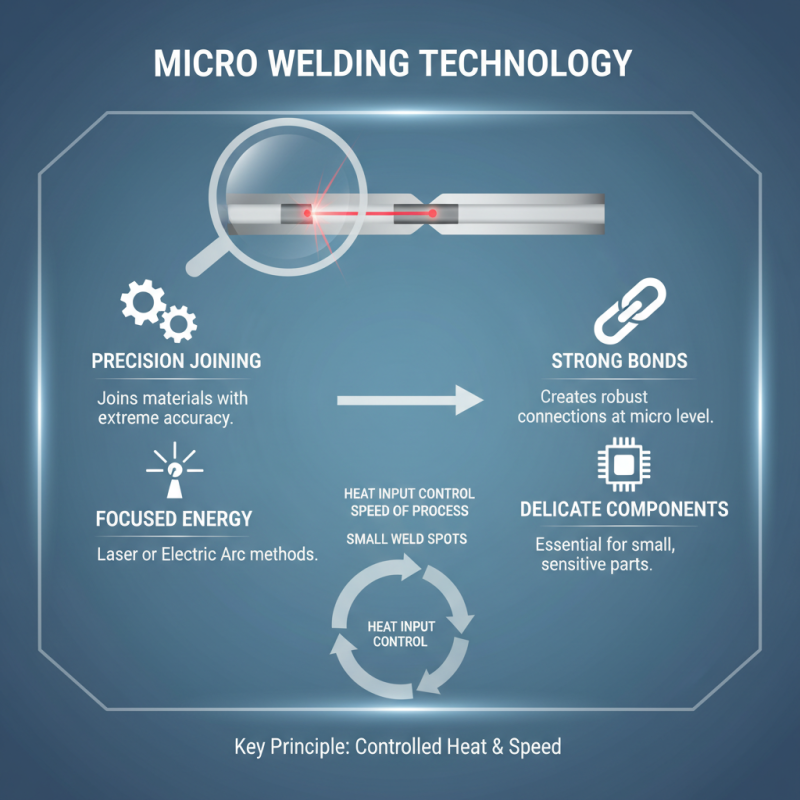

Principles Behind Micro Welding Technology

Micro welding is a specialized process that joins materials with precision. It uses focused energy to create strong bonds at micro levels. The principle behind micro welding technology relies on the control of heat input and the speed of the welding process. A micro welder typically employs laser or electric arc methods. These create very small weld spots, essential for delicate components.

In micro welding, the heat is concentrated in a tiny area. This minimizes thermal distortion. Materials like metals and plastics can be joined effectively. It’s particularly valuable in fields like electronics, automotive, and medical device manufacturing. Special attention is needed to avoid overheating, which could damage sensitive parts.

Tips: Always test your settings on scrap materials. This helps avoid costly mistakes. Monitor the weld pool carefully. Too much heat can lead to weak joints. Practice is key for mastery. Small adjustments can lead to better results. Experimentation is encouraged to refine techniques and outcomes.

Applications of Micro Welders in Various Industries

Micro welders have found their way into various industries, offering unique solutions to specific challenges. In electronics, for example, these tools create tiny welds on delicate components without causing damage. This precision is crucial when assembling smartphones or circuit boards. A small mistake in welding can lead to failures that cost time and money. The need for accuracy makes micro welders invaluable here.

In the jewelry industry, artisans use micro welding technology to join metals. It helps craft intricate designs and repairs without visible seams. A skilled operator can achieve results that enhance the beauty of the piece. However, not all micro welds are perfect. There's a learning curve, and inconsistent heat can result in weak joints. This highlights the need for constant practice and reflection on technique.

The medical field also benefits from micro welding. Devices often require small yet strong attachments. Surgical tools and implants can be made more reliable with micro welders, improving patient safety. Yet, quality control is essential here. Any flaws can lead to serious consequences. Therefore, operators must continuously assess their work to ensure efficacy and safety.

Advantages and Limitations of Using Micro Welders

Micro welders offer versatile solutions for intricate welding tasks. These tools excel at joining small components, especially in electronics and jewelry. Their ability to create tiny, precise welds is a significant advantage. However, the precision requires a high level of skill. Novice users may find it challenging to control the heat and avoid damaging components.

Another benefit of micro welders is their efficiency. They minimize the heat-affected zone. This leads to less distortion in delicate parts. However, with this advantage comes a limitation. Micro welding often requires specialized training. Not everyone can master the technique quickly. Additionally, the equipment can be costly.

While micro welders have their perks, they also have drawbacks. The learning curve can be steep. Moreover, not all materials can be welded successfully. It's crucial to assess the suitability of the welder for specific tasks. Each project may present unique challenges. Thus, careful planning is necessary before diving into micro welding.

Related Posts

-

Unlocking the Future: How Micro Welders Are Revolutionizing Precision Manufacturing

-

How to Choose the Best Tig Welder for Your Welding Projects

-

Exploring the Future: How Handheld Laser Welders Are Revolutionizing DIY Projects

-

Top 10 Benefits of Hand Held Laser Welding Machines You Need to Know

-

Top 10 Handheld Laser Welding Machines for Efficient Metal Joining

-

How to Choose the Best Laser Marking Systems for Your Business Needs