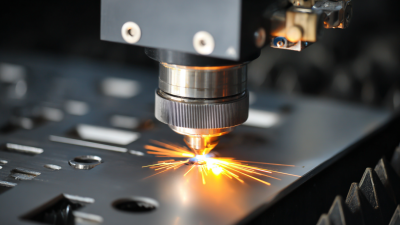

As the global automotive industry transitions toward electrification and lightweighting, laser welding technology for aluminum applications is rapidly evolving. This evolution is largely driven by the demand for high-strength, lightweight materials that enhance vehicle efficiency. With the laser welding market projected to grow to USD 4.2 billion at a CAGR of 3.7% from 2025 to 2035, it's crucial for manufacturers to stay ahead of the curve by adopting advanced welding techniques.

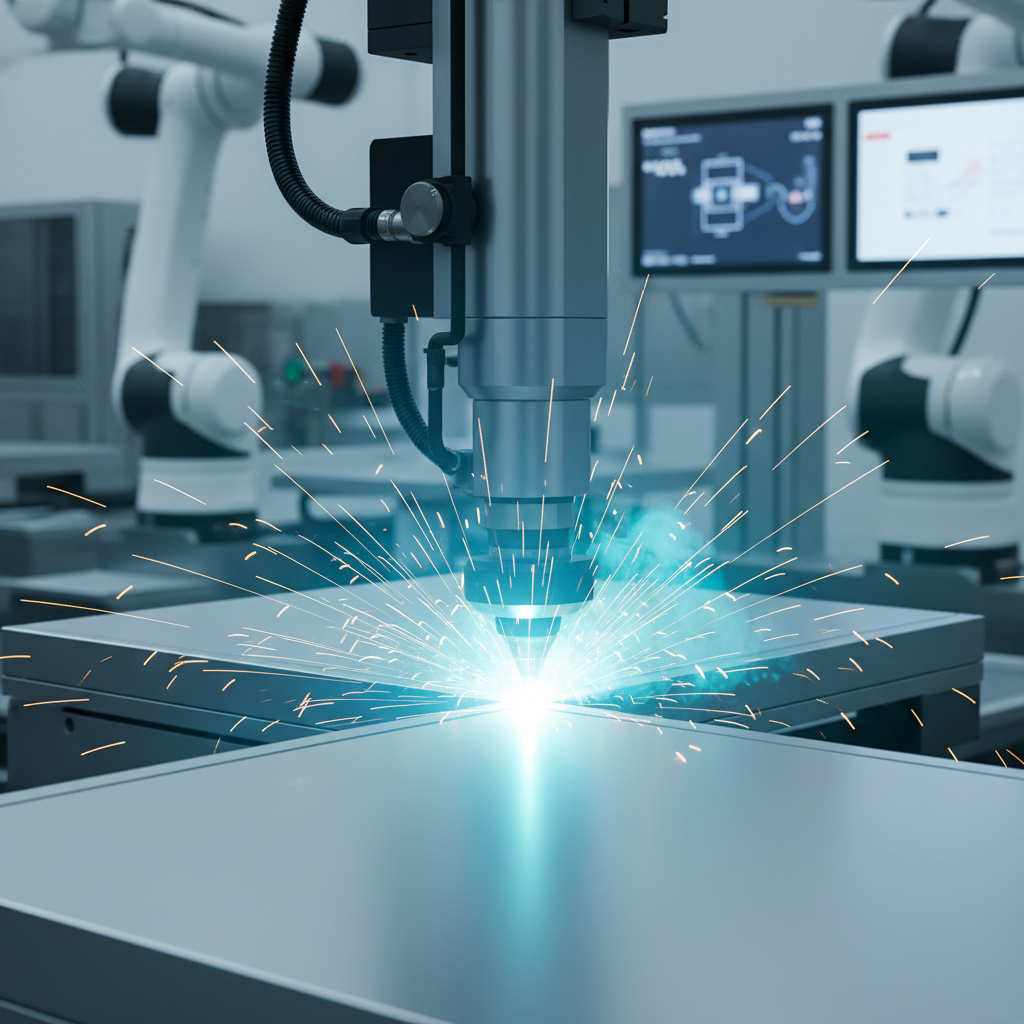

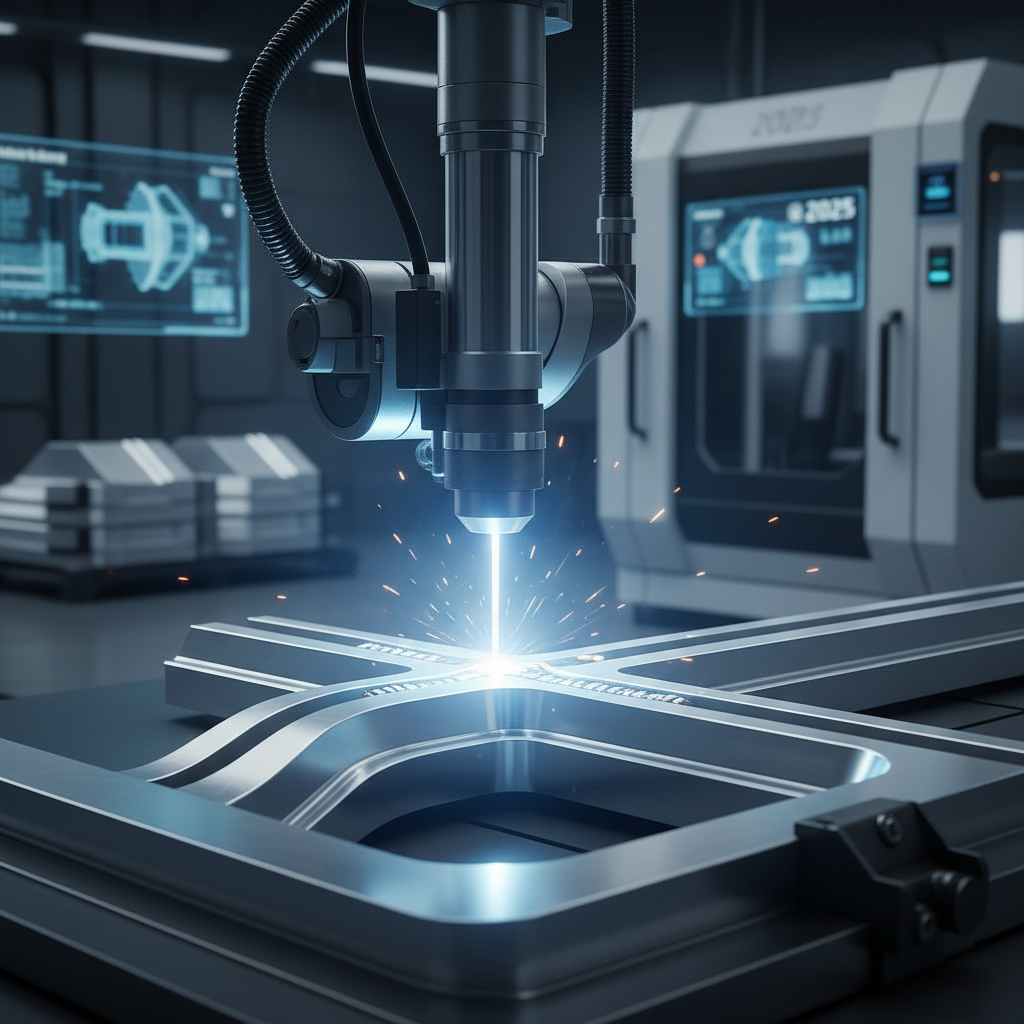

Future trends indicate an increased integration of automation and robotics in laser welding processes. This not only improves precision but also reduces manufacturing time, making it a compelling choice for high-volume production within the automotive sector. Furthermore, developments in laser beam technology are leading to better penetration and weld quality, making aluminum components more reliable than ever.

Tips:

1. Invest in training your workforce on the latest laser welding techniques to maximize efficiency and output quality.

2. Consider incorporating advanced monitoring systems to oversee the laser welding process, ensuring optimal performance and consistency.

3. Stay updated on the latest innovations in laser technology to maintain a competitive edge in the market.