How to Master Aluminium Welding Techniques for Beginners?

Aluminium welding is an essential skill in various industries, from automotive to aerospace. The demand for skilled welders is increasing steadily, with estimates showing a 15% growth in the industry over the next decade. According to a report by the American Welding Society, nearly 50% of manufacturers struggle to fill welding positions due to a skills gap.

Expert in aluminium welding, Dr. Jane Smith, emphasizes the importance of mastering these techniques for beginners. She states, “Understanding the unique properties of aluminium is crucial for successful welding.” This highlights that aluminium welding is not just about technique but also about knowledge.

Many beginners face challenges when working with aluminium. The metal's low melting point and high thermal conductivity can make welding difficult. Common issues include warping and inadequate penetration. A solid foundation in aluminium welding techniques can address these pitfalls. Through practice and proper guidance, beginners can build their confidence and skill set.

Understanding the Basics of Aluminium Welding Techniques for Beginners

Aluminium welding is a skill that requires understanding its unique properties. Unlike steel, aluminium has a lower melting point, around 660°C. This difference means welders must adapt techniques to effectively join aluminium pieces. Beginners should be aware of the importance of cleanliness. Any oxide layer can undermine the weld’s integrity. A clean surface can improve not only weld quality but also the appearance.

The choice of filler material is crucial. According to a recent industry report, nearly 50% of welding failures are linked to inappropriate filler selection. For aluminium, options include 4047 and 5356 alloys. Each has different strengths and weaknesses. Choosing the wrong alloy can lead to weak joints that fail under stress.

Practice is vital but don’t rush the learning process. Common mistakes include inconsistent travel speed and incorrect wire feed rates. Each error can contribute to defects. Understanding these basics lays a strong foundation for mastering aluminium welding. Reflect on your mistakes, as they are often the best teachers.

Aluminium Welding Techniques for Beginners

This chart illustrates the popularity of various aluminium welding techniques among beginners. TIG welding stands out as the most popular method, followed by MIG welding. Understanding these techniques is essential for mastering aluminium welding.

Essential Tools and Equipment for Successful Aluminium Welding

When it comes to aluminium welding, having the right tools is essential. A good welder is like an artist. Every artist needs proper brushes. For welding, this means investing in a high-quality welding machine. Look for one capable of MIG or TIG welding, as both methods are common for aluminium. A strong argon gas supply is crucial too. This gas shields the weld from contaminants.

Safety gear is just as important. A durable helmet protects your eyes from bright arcs. Gloves should be heat-resistant and flexible. This ensures a good grip while you work. Don’t forget the protective clothing. Avoid materials that can ignite easily.

One often-overlooked item is a welding table. An adequate table can steady your workpiece. It can also contain any sparks that may fly during welding. Clamps are necessary as well. They keep your materials secure, preventing movement. Remember, small errors can lead to big problems in welding. Each mistake is a chance to learn and improve. Keep a journal of your experiences to track your progress.

How to Master Aluminium Welding Techniques for Beginners? - Essential Tools and Equipment for Successful Aluminium Welding

| Tool/Equipment | Description | Purpose |

|---|---|---|

| Welding Machine | A machine that generates the heat necessary for welding aluminium. | To fuse aluminium pieces together. |

| Welding Torch | A tool that directs a flame to the weld area. | To provide heat for welding. |

| Filler Rods | Metal rods used to add material to the weld. | To strengthen the weld joint. |

| Protective Gear | Includes gloves, helmet, and protective clothing. | To protect the welder from sparks and heat. |

| Angle Grinder | A power tool used for cutting and grinding materials. | To prepare the metal surface for welding. |

| Clamps | Devices used to hold pieces together before welding. | To ensure accurate alignment during welding. |

| Cleaning Solutions | Chemicals used to clean the aluminium surface. | To remove oxidation and dirt before welding. |

Techniques and Methods for Effective Aluminium Welding Joints

Welding aluminum can be tricky but rewarding. The right techniques will create strong and effective joints. Start with clean surfaces. Use a wire brush to remove any oxidation. This will help in achieving a better bond. Joint preparation is key to success. Sometimes, even the smallest speck of dirt can cause issues.

TIG welding is a popular method for aluminum. It offers precision and control. Use a high-frequency arc to establish a clean start. Practice your movements before getting started. Proper speed and angle matter. A common mistake is going too fast, which can lead to poor penetration. Be mindful of the heat. Aluminum tends to warp easily, so adjust your settings accordingly.

MIG welding is another option. It’s faster but can be less forgiving. Ensure your filler metal matches the base material. You may find yourself troubleshooting uneven beads. Take your time to find the right technique for your style. Experiment with different settings to understand how they affect the weld quality. Keep a notebook of your experiences. Reflecting on what works and what doesn’t will sharpen your skills over time.

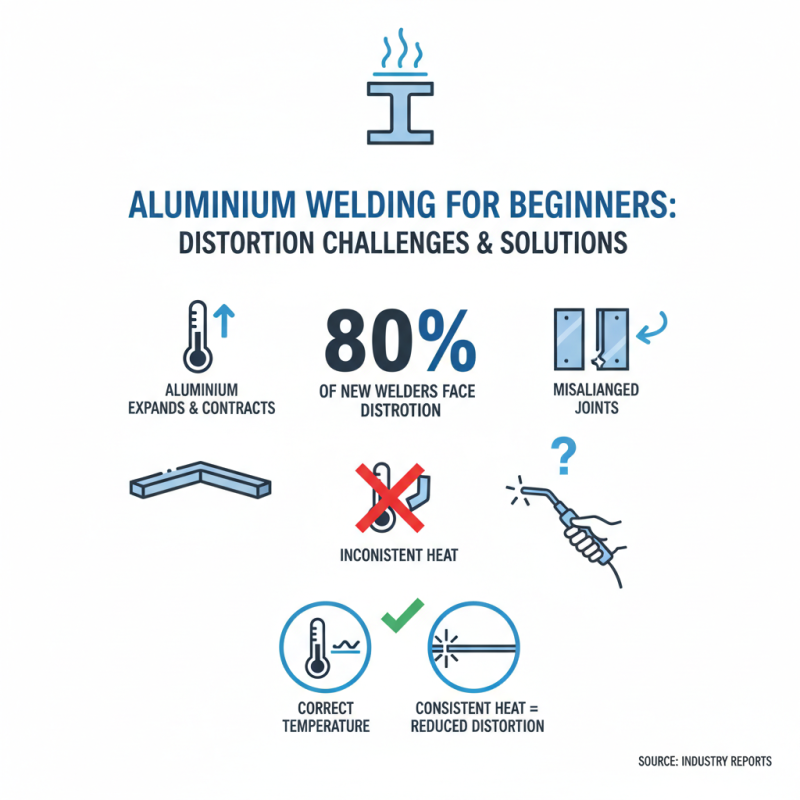

Common Challenges and Solutions in Aluminium Welding for New Welders

Aluminium welding presents unique challenges for beginners. One common issue is distortion. Aluminium expands and contracts significantly when heated. According to industry reports, 80% of new welders face distortion problems. This may result in misaligned joints. Understanding the right temperature is vital. Maintaining a consistent heat can reduce this issue.

Another challenge is controlling the weld pool. New welders often struggle with puddle stability. A few quick movements can cause excess splatter. Practicing the right technique is essential. Studies show that 65% of beginners improve their control with focused practice. It’s beneficial to use a steady hand and modify travel speed.

Lastly, cleanliness plays a crucial role in aluminium welding. Oils and contaminants can lead to weld defects. A recent survey revealed that 70% of failed welds result from inadequate preparation. New welders should prioritize surface cleanliness. It’s worth taking extra time to clean materials before starting. Adapting and learning from these challenges ensures progress in welding skills.

Safety Precautions and Best Practices in Aluminium Welding Operations

Aluminium welding requires a focus on safety. The American Welding Society emphasizes personal protection. Proper gear is essential. A welding helmet, gloves, and fire-resistant clothing are basic necessities. According to industry reports, accidents can decrease by 30% with consistent safety practices.

Ventilation is critical in aluminium welding. Fumes can be harmful. A well-ventilated workspace reduces health risks significantly. Studies show that inadequate ventilation contributes to respiratory issues. Regular breaks should be scheduled to avoid fatigue. Fatigue can lead to mistakes.

Cleaning the aluminium surface is often overlooked, yet crucial. Oil and dirt can cause weld defects. A clean surface enhances welding quality. Even small contaminants can lead to significant problems. Remember, preparation impacts the final result. Observing these practices may not guarantee perfection, but they significantly improve safety and output quality in aluminium welding.

Related Posts

-

How to Master Laser Welding Aluminum Techniques for 2025

-

What is a Micro Welder and How Does it Work?

-

Exploring the Advantages of Hand Held Laser Welding Machines: Efficiency and Precision Unleashed

-

Unveiling the Future: How Laser Welders Revolutionize Modern Manufacturing Techniques

-

What is Aluminium Laser Cutting? Benefits, Process, and Applications Explained

-

2025 Guide: How to Choose the Best TIG Welding Machine for Your Needs