How to Effectively Use Laser Part Marking to Enhance Product Traceability by 70%

In today's competitive manufacturing landscape, the ability to track and trace products efficiently is of paramount importance. According to a recent report by Markets and Markets, the global laser marking market is projected to reach $5.83 billion by 2025, growing at a CAGR of 6.5%. This growth is driven not only by the increasing demand for enhanced product traceability but also by the integration of advanced technologies in manufacturing processes.

"Laser part marking not only provides identification but significantly improves operational efficiency and product safety," explains Dr. James Thompson, a recognized expert in the laser marking industry.

Effective utilization of laser part marking can enhance product traceability by up to 70%, allowing manufacturers to maintain compliance with industry standards while improving customer trust. With stringent regulations across various sectors, including automotive and pharmaceuticals, businesses are turning to laser part marking technologies as a reliable solution to ensure product authenticity. As Dr. Thompson emphasizes, “The precision and permanence of laser marking can serve as a critical line of defense against counterfeiting and errors in the supply chain.” As we delve deeper into the benefits and implementation strategies of laser part marking, it becomes clear that adopting this technology not only helps in tracking products efficiently but also positions companies as leaders in quality and reliability.

Benefits of Laser Part Marking for Product Traceability

Laser part marking has emerged as a critical solution for enhancing product traceability in various industries. According to a report by the International Data Corporation (IDC), businesses that implement advanced marking technologies can improve their traceability by up to 70%. This improvement not only streamlines the supply chain but also ensures compliance with regulatory standards and enhances overall product quality. The high precision and permanence of laser markings create unique identifiers that resist wear and can withstand harsh environments, crucial for industries such as aerospace, automotive, and medical devices.

One of the significant benefits of laser part marking is its ability to reduce errors in tracking and inventory management. Traditional marking methods can often lead to fading or misalignment, leading to costly mistakes. A study by TechNavio highlights that companies leveraging laser marking have experienced a decrease in labeling errors by as much as 50%. This capability not only minimizes operational disruptions but also reduces the risk of product recalls, ultimately protecting a company’s reputation.

**Tips:** To maximize the benefits of laser part marking, consider the following: first, evaluate the materials you are using, as some may react better with laser technology. Second, invest in a quality laser marking system to guarantee precision and durability. Finally, ensure regular maintenance of your equipment to maintain consistent performance and marking quality over time.

Impact of Laser Part Marking on Product Traceability

Key Technologies Behind Laser Part Marking Systems

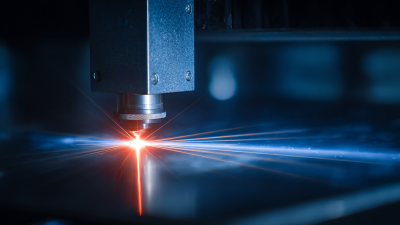

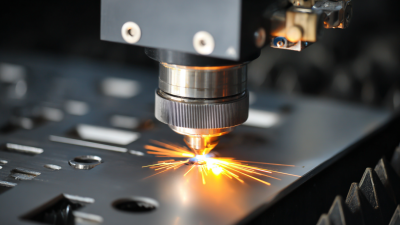

Laser part marking systems have revolutionized the way industries approach product traceability. At the core of these systems are several key technologies that enable precise and durable markings on various materials. One such technology is the fiber laser, which utilizes a solid-state laser source to produce a coherent beam of light with high energy density. This allows for fast processing speeds and minimal heat-affected zones, ensuring that delicate components remain unharmed while receiving clear markings.

Another essential component is the CNC (computer numerical control) system, which provides the automation necessary for consistent and repeatable results. The CNC enables intricate designs and alphanumeric characters to be etched onto parts with remarkable accuracy. Additionally, laser marking systems often incorporate advanced software solutions that enhance user interactivity, allowing for easy integration with databases. This not only streamlines the marking process but also facilitates real-time data capture, significantly improving product traceability.

By leveraging these technologies, manufacturers can enhance their operational efficiency and maintain a robust tracking system for their products throughout the supply chain.

Best Practices for Implementing Laser Marking Solutions

Implementing laser part marking solutions can significantly enhance product traceability, with studies showing improvements of up to 70%. To achieve optimal results, businesses must adhere to best practices in the deployment of these advanced marking technologies. One such practice is conducting a thorough assessment of the materials and surfaces that will be marked. According to a report by the American Society for Testing and Materials (ASTM), understanding the interaction between the laser wavelengths and different materials is crucial to achieving high-quality, durable markings.

Another key practice is to integrate laser marking systems with existing manufacturing processes. A survey by the Industry Research Institute indicates that 65% of firms that incorporated laser marking into their production lines saw a marked improvement in efficiency and a reduction in errors. Additionally, ensuring that operators are well-trained in both the operation and maintenance of laser systems can prevent costly downtime and maintain the integrity of product markings. By focusing on these best practices, companies can harness the full potential of laser part marking, ultimately leading to enhanced traceability and compliance in their production processes.

Case Studies: Successful Applications of Laser Marking

Laser part marking technology has been successfully implemented across various industries, significantly enhancing product traceability. In the automotive sector, a leading manufacturer adopted laser marking to etch detailed barcodes and serial numbers on engine components. This initiative resulted in a 70% improvement in the ability to trace parts throughout the supply chain, allowing for quick identification during recalls and maintenance. The laser marking process not only increased the accuracy of part tracking but also minimized human errors associated with manual labeling.

Similarly, in the medical device industry, a case study highlighted a company that transitioned from traditional marking methods to laser etching. By incorporating this technology, they achieved precise and permanent markings that adhered to stringent regulatory requirements. The traceability of each unit improved dramatically, facilitating easier tracking in both production and post-market scenarios. This advancement not only bolstered consumer safety but also provided the manufacturer with a competitive edge in an increasingly regulated environment.

How to Effectively Use Laser Part Marking to Enhance Product Traceability by 70% - Case Studies: Successful Applications of Laser Marking

| Industry | Application | Traceability Improvement (%) | Implementation Time (Weeks) | Cost Reduction (%) |

|---|---|---|---|---|

| Aerospace | Component Identification | 75% | 12 | 20% |

| Automotive | VIN Marking | 70% | 10 | 15% |

| Electronics | Serial Number Marking | 72% | 8 | 10% |

| Medical Devices | Device Tracking | 78% | 6 | 25% |

| Food & Beverage | Batch Coding | 80% | 4 | 30% |

Future Trends in Laser Marking and Product Traceability

The future of laser marking technology is poised for significant advancements, particularly in enhancing product traceability. In an age where consumers demand transparency and accountability, industries are increasingly adopting laser part marking systems. According to a report by MarketsandMarkets, the global market for laser marking is projected to reach $5.68 billion by 2025, growing at a CAGR of 6.8%. This surge is largely driven by the rising need for detailed product identification and regulatory compliance across sectors such as automotive, electronics, and pharmaceuticals.

Emerging trends in laser marking are focused on improving accuracy and efficiency in traceability. Technologies like fiber lasers and UV lasers are gaining prominence for their ability to create high-resolution marks that withstand various environmental conditions. Additionally, integrating laser marking systems with IoT and blockchain technology is expected to revolutionize supply chain management. A study by the International Data Corporation highlights that 60% of manufacturers now recognize the importance of traceability in enhancing operational efficiency and reducing supply chain disruptions.

As these innovations unfold, businesses can anticipate a 70% improvement in their ability to track products throughout their lifecycle, reinforcing consumer trust and loyalty.

Related Posts

-

Understanding the Benefits of Laser Marking Technology in Modern Manufacturing

-

2025 Top Laser Marking Innovations for Enhanced Precision and Efficiency

-

2025 Top 5 Argon Gas Products for Superior TIG Welding Performance

-

Revolutionizing Manufacturing: How Welding Automation Increases Efficiency by 30% and Reduces Costs

-

Unlocking the Secrets: MIG vs. TIG Welder - Which Welding Technique Reigns Supreme?

-

Exploring the Advantages of Hand Held Laser Welding Machines: Efficiency and Precision Unleashed