Why Invest in a TIG Welding Machine for Your Next Project?

In recent years, the demand for high-quality welds in various industries has surged, driving a growing interest in advanced welding technologies. According to the American Welding Society, the welding industry contributes over $4 billion to the U.S. economy and is projected to witness a significant growth rate of approximately 4.1% annually. In this context, the "tig welding machine" has emerged as a critical tool for professionals seeking precision and versatility in their welding operations.

TIG (Tungsten Inert Gas) welding is revered for its ability to produce clean, strong welds on a vast array of metals, including stainless steel and aluminum. With the rise in manufacturing and repair industries, the utilization of TIG welding machines is becoming increasingly essential. Data from the Fabricators & Manufacturers Association indicates that more than 50% of manufacturers are investing in advanced welding technologies to enhance efficiency and improve quality. This investment not only boosts productivity but also reduces material waste, exemplifying the importance of incorporating modern welding equipment into any serious fabrication strategy.

As market dynamics evolve, understanding the benefits and applications of a TIG welding machine becomes paramount for anyone engaged in metalworking. Whether for intricate projects, high-strength applications, or even for hobbyists aiming for superior craftsmanship, investing in a TIG welding machine can significantly enhance the outcome of your next welding project.

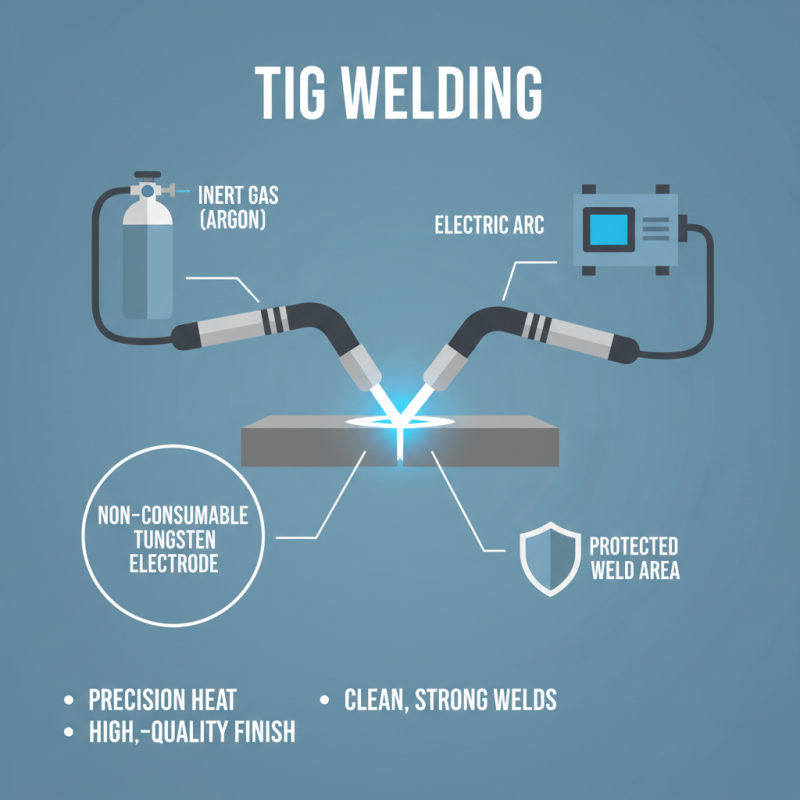

Understanding the Principles of TIG Welding Technology

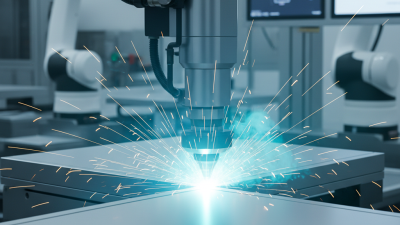

TIG (Tungsten Inert Gas) welding is a sophisticated arc welding process that relies on a non-consumable tungsten electrode to produce the weld. The primary principle behind TIG welding is to create a precise and controllable heat source using a combination of a gas shield and a concentrated electric arc. During the welding process, an inert argon gas is used to protect the weld area from oxidation and contamination, which is critical for achieving high-quality welds. This method allows for a cleaner and more efficient weld compared to other welding techniques, making it ideal for projects where finish quality is paramount.

One of the key advantages of TIG welding technology is its versatility in working with a wide range of materials, including stainless steel, aluminum, and even exotic metals. The process allows for the manipulation of the arc length and travel speed, providing greater control over the weld pool. This level of control is especially beneficial in applications that require precision, such as aerospace and automotive industries, or in artistic metalworking. Furthermore, TIG welding can produce both thin and thick materials with ease, making it a valuable addition to any fabricator's toolkit. Understanding these principles will not only optimize project outcomes but also enhance overall welding skills.

Advantages of Using TIG Welding Machines for Various Projects

TIG welding, or tungsten inert gas welding, is increasingly recognized as a superior method for various types of projects due to its precision and versatility. According to a report by the American Welding Society, the global welding market is expected to reach $30 billion by 2026, with TIG welding becoming a preferred choice for many industrial applications. This method is particularly advantageous when working with thin materials, such as aluminum and stainless steel, where maintaining a high level of control over heat input is critical. The ability to produce clean and strong welds while minimizing distortion makes TIG welding ideal for intricate fabrications in sectors like aerospace, automotive, and art.

In addition to its precision, TIG welding offers a range of benefits that enhance productivity and quality. A study published in the Journal of Materials Processing Technology highlighted that TIG welding provides a lower cost of ownership due to less spatter and reduced cleanup time compared to other welding methods. The inert gas shielding protects the weld pool from contamination, resulting in fewer defects and a higher-quality finish. This results in less rework and downtime, providing significant operational efficiencies for manufacturers. Moreover, TIG welders report increased job satisfaction as they enjoy the artistry involved in the process, making it not just a practical choice, but also an appealing one for skilled welders.

Advantages of Using TIG Welding Machines for Various Projects

Cost-Benefit Analysis of Investing in a TIG Welding Machine

Investing in a TIG welding machine for your next project can offer substantial long-term benefits when evaluated through a cost-benefit analysis. TIG welding, known for producing high-quality and precise welds, is particularly effective for materials like stainless steel and aluminum. According to the American Welding Society, the demand for skilled TIG welders is projected to increase by 12% over the next decade, indicating a growing market where quality workmanship is paramount. This uptick in demand can lead to higher rates for professional welders, making owning a TIG machine a potentially lucrative investment.

When considering the costs associated with purchasing a TIG welding machine, it is essential to weigh them against the benefits of quality and versatility. Initially, the upfront investment may seem high, with prices ranging from $1,000 to over $5,000 depending on features and capabilities. However, the durability and efficiency of these machines can lead to significant savings on labor and material over time. For example, precise welding reduces the need for additional machining and post-weld finishing, often translating to lower production costs.

Tips: Before purchasing a TIG welding machine, evaluate your specific project needs, including the materials you’ll be welding and the required thickness. Additionally, consider training resources available to ensure you can maximize the machine’s potential. Investing in high-quality consumables and maintaining your equipment will also enhance performance and longevity, providing greater returns on your initial investment.

Why Invest in a TIG Welding Machine for Your Next Project? - Cost-Benefit Analysis

| Dimension | Details |

|---|---|

| Initial Investment Cost | $3,000 - $5,000 |

| Average Lifespan | 10 - 15 years |

| Maintenance Cost per Year | $200 - $400 |

| Energy Consumption per Hour | 10 - 20 kWh |

| Skill Level Required | Intermediate to Advanced |

| Material Versatility | Steel, Aluminum, Copper, and more |

| Potential Job Opportunities | Construction, Automotive, Aerospace, and more |

| Return on Investment (ROI) | 15% - 30% annually |

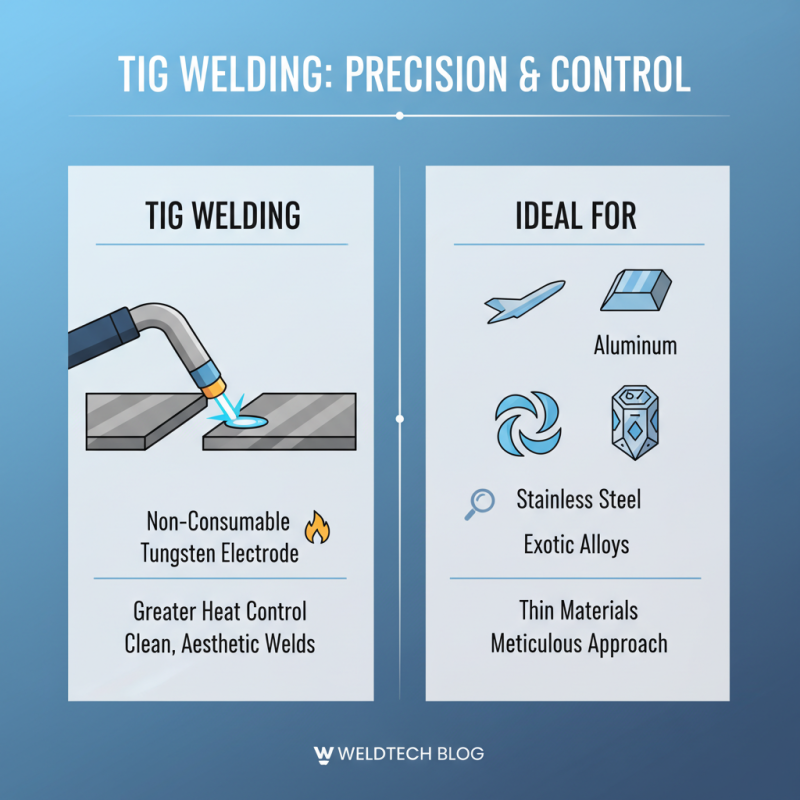

Comparing TIG Welding with Other Welding Methods

TIG welding, or tungsten inert gas welding, is often favored for projects requiring precision and control. Unlike MIG (metal inert gas) welding, which utilizes a continuous wire feed, TIG welding employs a non-consumable tungsten electrode to produce the weld. This allows for greater manipulation and offers the welder the ability to control the heat more effectively, resulting in cleaner and more aesthetically pleasing welds. This is particularly beneficial for thin materials that demand a meticulous approach, such as aluminum, stainless steel, or exotic alloys.

When comparing TIG welding to stick welding, for instance, the differences become even more pronounced. Stick welding is typically more portable and can be used outdoors without the need for gas shielding; however, it often produces a rougher finish and is less suitable for delicate tasks. TIG welding, on the other hand, excels in creating strong and precise welds, making it ideal for applications in industries such as aerospace, automotive, and art fabrication where finish quality is paramount. The choice between these methods largely depends on the specific requirements of the project, but for those prioritizing finesse and accuracy, investing in a TIG welding machine can significantly enhance the overall results.

Key Features to Consider When Choosing a TIG Welding Machine

When selecting a TIG welding machine for your next project, it's crucial to consider several key features that can significantly impact the quality and efficiency of your work. One of the most important features is the power output of the machine, typically measured in amperage. According to industry reports, machines with adjustable amperage settings are preferred, as they allow for greater control over the welding process, particularly when working with thinner materials or requiring precise welds. A power range of 200-250 amps is commonly recommended for versatile applications, providing the flexibility needed for both introductory and advanced welding tasks.

Another critical aspect to evaluate is the duty cycle of the TIG welding machine. Duty cycle refers to the elapsed time, usually expressed in a percentage, that a welding machine can operate continuously within a 10-minute period before it needs to cool down. A higher duty cycle, typically between 60% to 100%, is essential for more extensive projects, enabling longer operational times without overheating. As per findings from the American Welding Society, machines with a 40% duty cycle may suffice for casual users, but professionals often seek those with 60% or more to ensure consistent performance during prolonged use.

Portability and ease of use should also be considered, especially for welders who may need to transport their equipment to various job sites. Weighing the machine’s weight and design, as well as user-friendly interfaces, can enhance productivity. Reports indicate that models with ergonomic handles and wheels can effectively reduce strain and improve maneuverability, a feature particularly beneficial for those requiring mobility in their work environments. By focusing on these key features, welders can not only enhance their capabilities but also ensure that they are making a sound investment in their equipment.

Related Posts

-

Top 10 Benefits of Gas Tungsten Arc Welding You Need to Know

-

Exploring the Future: How Handheld Laser Welders Are Revolutionizing DIY Projects

-

What is Aluminium Laser Cutting? Benefits, Process, and Applications Explained

-

How to Effectively Use Laser Part Marking to Enhance Product Traceability by 70%

-

Revolutionizing Manufacturing: How Welding Automation Increases Efficiency by 30% and Reduces Costs

-

How to Master Laser Welding Aluminum Techniques for 2025