Top 10 Handheld Laser Welding Machines for Efficient Metal Joining

In recent years, the demand for efficient and versatile metal joining solutions has surged, with the handheld laser welding machine emerging as a leading technology in the field. According to a report by MarketsandMarkets, the global market for laser welding machines is projected to reach $2.4 billion by 2026, growing at a CAGR of 5.7%. This growth can be attributed to the increasing need for high-quality welds in various industries, including automotive, aerospace, and fabrication.

Experts in the field highlight the transformative potential of handheld laser welding machines. Dr. Emily Tran, a renowned laser technology researcher, states, "Handheld laser welding machines represent a significant shift in how we approach metal joining, allowing for greater precision and flexibility than traditional methods." The ability to perform accurate welds in hard-to-reach areas with minimal heat distortion has positioned these machines as indispensable tools for manufacturers striving for efficiency and cost-effectiveness.

The significance of handheld laser welding technology cannot be overstated, as it not only enhances productivity but also reduces material waste and energy consumption. As industries continue to adopt advanced welding techniques, the handheld laser welding machine stands at the forefront of these advancements, paving the way for innovative manufacturing processes that meet the challenges of the modern market.

Overview of Handheld Laser Welding Technology

Handheld laser welding technology has revolutionized the metal joining process, providing a flexible, efficient solution for various industrial applications. Unlike traditional welding methods, handheld laser welding utilizes concentrated laser beams to create precise and strong welds, significantly reducing the heat-affected zone. This not only leads to cleaner welds but also minimizes the distortion of the base materials. Moreover, these machines are user-friendly and can be operated in tight spaces, making them suitable for both on-site repairs and factory settings.

When working with handheld laser welding machines, it is essential to follow certain tips for optimal results. Always ensure that the materials being welded are clean and free of contaminants to achieve the best bond possible. Additionally, understanding the settings of your machine, such as laser power and speed, is crucial. Adjusting these parameters based on the thickness and type of metal being welded can make a significant difference in the quality of the weld.

Safety cannot be overlooked in handheld laser welding operations. Operators should wear appropriate protective gear, including laser safety glasses, to guard against the intense light produced during welding. Furthermore, having a well-ventilated workspace will help mitigate exposure to any fumes generated during the process. By implementing these practices, users can enhance their welding efficiency while ensuring a safe working environment.

Key Features to Look for in Handheld Laser Welding Machines

When selecting a handheld laser welding machine, several key features should be prioritized to ensure efficient metal joining. First, the machine's laser power is crucial; it determines the material thickness it can handle and the overall welding speed. Typically, a power range between 1000 to 2000 watts is ideal for most applications, allowing for effective welding on a variety of metals, including stainless steel and aluminum.

Additionally, portability and ergonomics are essential, as operators will often need to maneuver the machine in tight spots, where ease of handling can significantly impact productivity.

Another important feature is the cooling system, which plays a vital role in maintaining optimal operation during extended use. A robust cooling mechanism helps prevent overheating, thereby prolonging the lifespan of the equipment and ensuring consistent weld quality.

Furthermore, consider the user interface and control options; intuitive controls and easy-to-read displays enhance user experience, making it simpler to adjust settings based on specific welding tasks.

Finally, ensure that the machine has adequate safety features, such as protective shields and safety locks, to safeguard users during operation.

Top Brands and Models in Handheld Laser Welding

Handheld laser welding machines have revolutionized the metal joining industry, allowing for precision and efficiency in various applications. These machines are designed for versatile use, catering to both small-scale and industrial tasks. The technology employs powerful laser beams to create strong welds, significantly reducing the time required for traditional welding methods. As the market expands, several top brands have emerged, each offering unique models that cater to specific needs and preferences in welding.

When considering a handheld laser welding machine, it is essential to evaluate the key features offered by different brands and models. Factors such as portability, energy efficiency, and ease of use play crucial roles in determining the best fit for specific tasks. Advanced features, such as adjustable power settings and integrated cooling systems, enhance the performance and longevity of these machines. Additionally, many top brands focus on user-friendly designs that facilitate quick setup and operation, making them suitable for both seasoned professionals and beginners alike in the metalworking field.

Top 10 Handheld Laser Welding Machines for Efficient Metal Joining

| Model | Wattage | Weight (kg) | Max Welding Thickness (mm) | Cooling Type | Operating Voltage (V) |

|---|---|---|---|---|---|

| LaserWeld 1000 | 1000W | 5.2 | 8 | Air | 220 |

| QuickLaser 1500 | 1500W | 6.5 | 10 | Water | 230 |

| MightyWeld Pro | 2000W | 7.0 | 12 | Air | 220 |

| FlexiWeld 500 | 500W | 4.0 | 5 | Passive | 110 |

| UltraLaser 1200 | 1200W | 5.5 | 9 | Water | 240 |

| ProWeld 1800 | 1800W | 6.8 | 11 | Air | 220 |

| SpeedyWeld 1600 | 1600W | 7.2 | 10 | Water | 230 |

| CompactWeld 800 | 800W | 5.0 | 7 | Air | 220 |

| TitanWeld 3000 | 3000W | 8.5 | 15 | Water | 240 |

| EconoWeld 100 | 100W | 3.0 | 2 | Passive | 110 |

Comparison of Performance Metrics in Laser Welding Machines

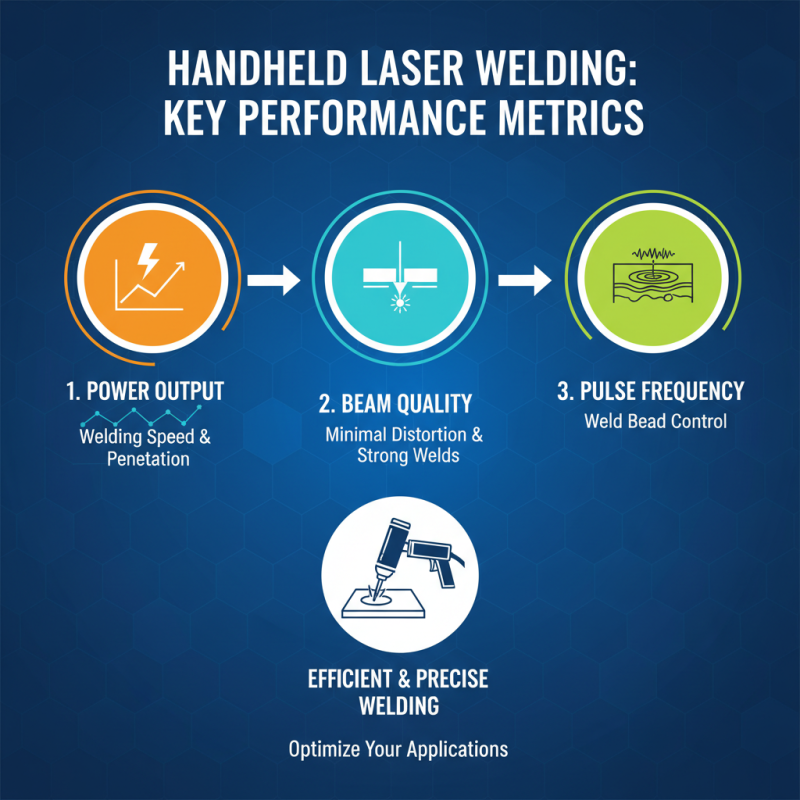

When evaluating handheld laser welding machines, performance metrics play a crucial role in determining their efficiency and suitability for various applications. Key metrics include power output, beam quality, and pulse frequency, all of which directly influence the welding speed and the depth of penetration. High power output allows for quicker welds, especially in thicker materials, while a superior beam quality ensures a narrower heat-affected zone, minimizing distortion and enhancing the integrity of the weld. Additionally, pulse frequency can affect the melt pool dynamics, making it essential for achieving precise control over the weld bead formation.

Another important aspect to consider is the cooling efficiency of the welding machine. Efficient cooling systems prevent overheating during prolonged use, ensuring consistent performance and longevity of the equipment. Moreover, user-friendliness and ergonomic design contribute to overall efficiency, as operators can achieve better precision and control with less fatigue. This is particularly notable in challenging environments where accessibility is limited. By comparing these performance metrics, users can better identify the most suitable handheld laser welding machine for their specific metal joining needs, driving improvements in productivity and quality within their operations.

Applications and Industries Benefiting from Laser Welding Technology

Laser welding technology has emerged as a pivotal innovation in various industries, enhancing productivity and precision in metal fabrication. One of the most significant applications is in the automotive sector, where robust and lightweight components are crucial for improving fuel efficiency and safety. Laser welding provides seamless joints that maintain the integrity of materials, allowing manufacturers to create complex geometries without compromising strength. This technology has revolutionized the way automotive parts are joined, resulting in lighter vehicles with enhanced performance characteristics.

Additionally, the aerospace industry greatly benefits from handheld laser welding machines, which facilitate the joining of high-strength alloys and titanium components. The precision of laser welding ensures minimal heat input, reducing the risk of warping or altering the metallurgical properties of sensitive materials. This capability is vital in aircraft manufacturing, where safety and reliability are paramount. Beyond aerospace and automotive applications, industries such as electronics and medical device manufacturing also harness laser welding for its efficiency and adaptability, allowing for intricate designs and robust connections in compact spaces. The versatility of handheld laser welding machines positions them as essential tools across these diverse sectors, driving advancements in technology and manufacturing processes.

Top 10 Handheld Laser Welding Machines for Efficient Metal Joining

This chart illustrates the efficiency of the top 10 handheld laser welding machines in various applications and industries that benefit from laser welding technology.

Related Posts

-

Best Handheld Laser Welder for Precision and Portability in 2023

-

Exploring the Advantages of Hand Held Laser Welding Machines: Efficiency and Precision Unleashed

-

Best Fiber Laser Welder Options for Precision and Efficiency in 2023

-

Top 10 Benefits of Hand Held Laser Welding Machines You Need to Know

-

Exploring the Future: How Handheld Laser Welders Are Revolutionizing DIY Projects

-

Top Features of the Best Laser Welding Guns for Precision Metalwork