2025 Guide: How to Choose the Best TIG Welding Machine for Your Needs

As the demand for high-precision welding continues to rise across various industries, selecting the right TIG welding machine has become critical for professionals and hobbyists alike. According to a recent report by Allied Market Research, the global welding equipment market is projected to reach $24.57 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.8% from 2020 to 2027. This surge underscores the importance of choosing the right tools, as the quality and efficiency of TIG welding directly impact production capabilities and final product integrity.

In 2025, understanding your specific needs is essential for selecting the best TIG welding machine. Factors such as power requirements, portability, and ease of use play a significant role in this decision. The right machine not only enhances overall operational efficiency but also contributes to improved weld quality. Furthermore, industry experts emphasize the need for staying updated with the latest technological advancements, as innovations in welding machines continue to evolve, providing enhanced features and capabilities. Making informed choices today ensures a competitive edge in tomorrow's ever-evolving market.

Understanding TIG Welding: Principles and Applications

TIG welding, or Tungsten Inert Gas welding, is one of the most precise welding techniques available, widely used in various industries for its ability to create high-quality welds on thin materials. The fundamental principle behind TIG welding involves the use of a non-consumable tungsten electrode to produce an electric arc. This arc melts the base metals to be welded while an inert gas, typically argon, protects the weld area from contamination. This process not only ensures a clean weld but also allows for greater control and finesse, making it ideal for delicate tasks and materials such as aluminum, stainless steel, and magnesium.

In addition to its precision, TIG welding offers a range of applications in sectors like aerospace, automotive, and fabrication. It is especially valued in settings where aesthetics and strength are critical, as the final weld is visually appealing and structurally sound. Moreover, the ability to control the heat input allows welders to work on a variety of thicknesses and types of metals, making TIG welding a versatile choice for professional and amateur welders alike. Understanding these principles and applications will significantly aid in selecting the right welding equipment that matches specific project requirements and skill levels, ensuring the best possible outcomes in welding endeavors.

Key Features to Look for in a TIG Welding Machine

When selecting a TIG welding machine, understanding the key features can significantly impact your welding experience and outcomes. One of the most crucial aspects to consider is the machine's amperage range. A wider amperage range allows for more versatility, enabling users to weld thin materials with low amperage while also tackling thicker metals with higher settings. This flexibility is essential for diverse projects, whether you're working on automotive repairs or artistic metal fabrication.

Another important feature is the type of welding torch that comes with the machine. A high-quality torch will provide better control and comfort, allowing you to maintain precision during welding. Additionally, check for ergonomic designs and ease of replacement for consumables, as these factors contribute to the overall efficiency and user experience.

Lastly, consider the machine's duty cycle, which indicates how long the welder can operate at a given output before needing to cool down. A higher duty cycle ensures extended work periods without interruptions, making it a critical feature for professional tasks or heavy usage scenarios.

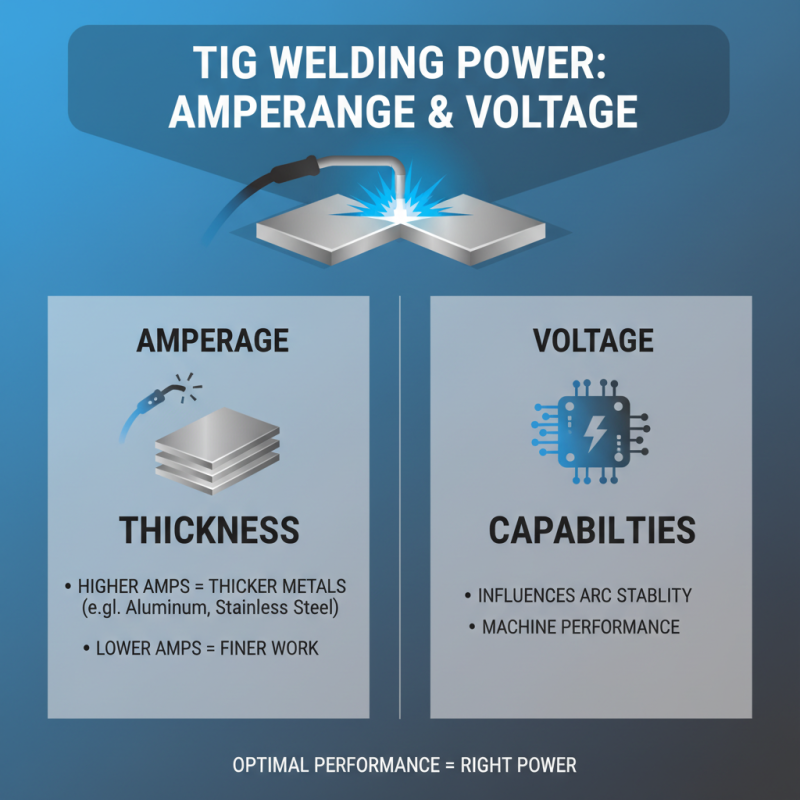

Evaluating Power Requirements: Amperage and Voltage Considerations

When selecting a TIG welding machine, understanding power requirements is crucial for achieving optimal performance. Two primary factors to consider are amperage and voltage, both of which significantly influence the machine's capabilities. Amperage determines the thickness of the metal you can weld; higher amperage allows for welding thicker materials, while lower amperage is suitable for finer work. For example, if you plan to work with aluminum or stainless steel, you'll need a machine that can deliver sufficient amperage for effective penetration and weld quality.

Voltage is equally important, as it impacts the arc stability and control during the welding process. Lower voltage is generally preferred for thin materials as it provides better control and less distortion, while higher voltage can be beneficial for thicker materials and those requiring deeper penetration. Additionally, considering the input voltage options, such as 110V or 220V, is vital for ensuring compatibility with your power supply. Making the right choices in amperage and voltage will help you select a TIG welding machine that not only meets your specific requirements but also enhances your welding experience.

Portability vs. Stationary Models: Choosing the Right Setup

When selecting a TIG welding machine, one critical consideration is the type of setup that best aligns with your needs: portability versus stationary models. Portable TIG welders are ideal for those who require mobility in their work environment. They are generally lightweight and compact, making them suitable for fieldwork or projects that take place in various locations. These machines often run on standard power outlets or can be powered by generators, providing flexibility. If you frequently travel to job sites or need a welder that can easily be transported, a portable model may be the most practical choice.

On the other hand, stationary TIG welding machines are designed for use in fixed locations, such as workshops or manufacturing setups. These models usually offer more robust features, greater power capacity, and enhanced stability, which can lead to improved welding performance for heavy-duty applications. While they lack the mobility of portable options, stationary machines often provide a higher degree of precision and features tailored for extensive projects. If your work primarily takes place in a single location and involves intricate welding tasks, investing in a stationary model may provide the best results for your welding requirements.

2025 TIG Welding Machine Comparison: Portability vs. Stationary Models

Top Brands and Models: A Comparison of Market Leaders in 2025

When selecting a TIG welding machine, understanding the landscape of top brands and models in 2025 is crucial for making an informed decision. Each leading brand typically excels in specific areas—such as portability, versatility, or advanced features—that cater to a diverse range of welding applications. As you compare options, consider elements like the machine's power output, ease of use, and additional functionalities that can enhance your welding experience. High-performance models often come with features like adjustable frequency, which allows for better control when welding materials of varying thicknesses, making the process more efficient.

In addition to technical specifications, the reputation and customer service of a brand should also play a part in your comparison. Leading brands of 2025 are generally recognized for their reliability and innovative technology. It's beneficial to explore user reviews and feedback to gauge real-world performance and satisfaction. Additionally, evaluating warranty terms and available support can provide insights into the reliability and longevity of the units you consider. This year, brands that prioritize customer experience alongside robust performance are likely to stand out, giving you the confidence to invest in a machine tailored to meet your specific welding needs.

Related Posts

-

Top 10 Tips for Choosing the Best TIG Welding Machine for Your Needs

-

Why Invest in a TIG Welding Machine for Your Next Project?

-

How to Choose the Best Tig Welder for Your Welding Projects

-

Top 10 Benefits of Gas Tungsten Arc Welding You Need to Know

-

How to Effectively Use Laser Part Marking to Enhance Product Traceability by 70%

-

Exploring the Future: How Handheld Laser Welders Are Revolutionizing DIY Projects