Top 10 Fiber Laser Welder Benefits for Precision Metal Fabrication

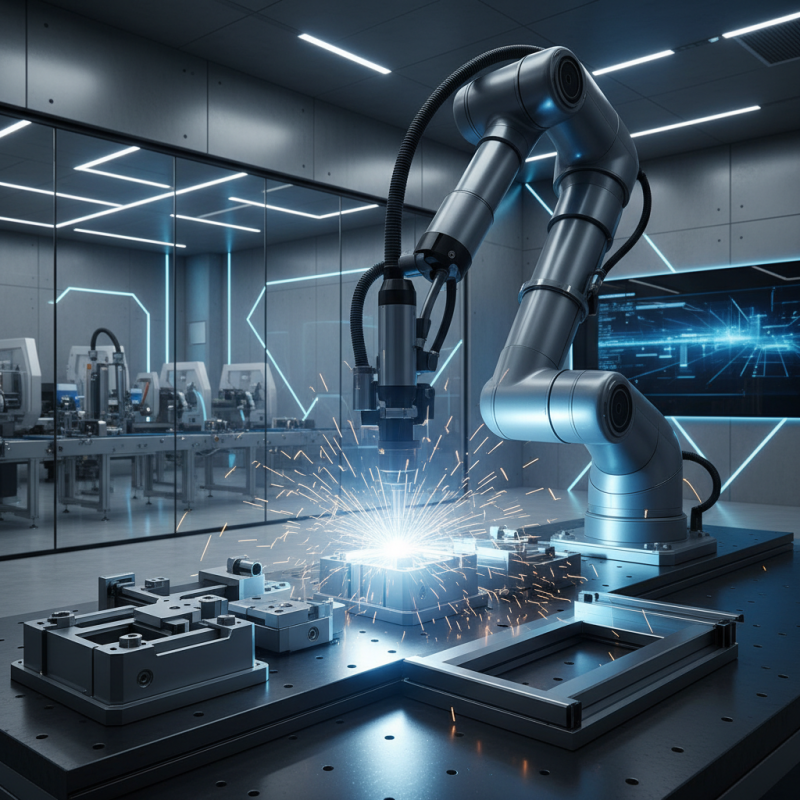

In the ever-evolving landscape of precision metal fabrication, the role of technology cannot be overstated. One of the most significant innovations in recent years is the fiber laser welder, a tool that has transformed manufacturing processes across various industries. According to John Adams, a renowned expert in laser technology, “The advent of fiber laser welders has not only improved the quality of welds but also enhanced overall production efficiency.” This assertion underscores the essential benefits that fiber laser welders bring to modern fabrication.

As manufacturers seek to remain competitive, understanding the advantages of fiber laser welding becomes paramount. These advanced tools offer unmatched precision, speed, and versatility, enabling businesses to meet the demands of an increasingly rigorous marketplace. By leveraging fiber laser technology, fabricators can achieve superior results that traditional welding methods simply cannot match. As we delve deeper into the top ten benefits of fiber laser welders, it is clear that this technology is not just a passing trend but a vital component of future metalworking solutions.

Understanding Fiber Laser Technology in Metal Fabrication

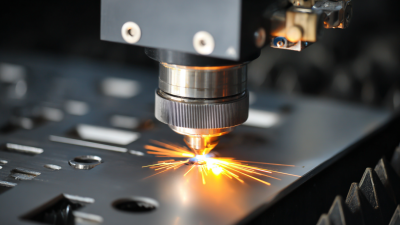

Fiber laser technology has revolutionized the metal fabrication industry, offering unparalleled precision and efficiency in welding processes. By utilizing a solid-state laser source, fiber lasers produce a concentrated beam of light that can be focused onto a small spot, resulting in exceptional energy density. This precision allows for intricate welds on thin materials, making it an ideal choice for intricate designs and components that require tight tolerances. The technology's ability to quickly and accurately cut through various metals, including steel, aluminum, and copper, enhances workflow and reduces production time.

Moreover, the flexibility of fiber laser systems boosts their appeal in metal fabrication. The lasers can be easily adjusted for different materials and thicknesses, providing versatility in applications from automotive to aerospace. The minimal heat affected zone ensures that the surrounding material remains undistorted, further contributing to the high-quality finishes that modern industries demand. As metal fabrication continues to evolve, understanding and leveraging fiber laser technology becomes pivotal for manufacturers aiming to enhance productivity and maintain competitive advantages in the market.

Top 10 Fiber Laser Welder Benefits for Precision Metal Fabrication

Enhanced Precision: How Fiber Lasers Improve Welding Accuracy

Fiber laser technology has revolutionized the field of precision metal fabrication, particularly when it comes to welding accuracy. The use of fiber lasers in welding applications allows for a focused beam of light that can be finely adjusted to achieve exceptional precision. This level of accuracy is critical in industries such as aerospace and automotive, where even the slightest misalignment can lead to significant issues.

Unlike traditional welding methods, fiber lasers can create narrower heat-affected zones, resulting in cleaner welds and reduced thermal distortion of the materials being joined.

Unlike traditional welding methods, fiber lasers can create narrower heat-affected zones, resulting in cleaner welds and reduced thermal distortion of the materials being joined.

Tips: For optimal results, ensure that your fiber laser welder is appropriately calibrated before starting a project. Regular maintenance checks can significantly enhance the performance and longevity of your equipment. Additionally, utilizing advanced software for process simulation can help predict potential challenges and improve your overall welding strategy.

Moreover, the ability to easily automate fiber laser welding processes not only enhances repeatability but also significantly reduces human error. Automation tools can help in maintaining consistent weld quality, which is essential for high-volume production environments. The seamless integration of fiber lasers with robotic systems further streamlines workflows while retaining high standards of accuracy.

By leveraging these advancements, manufacturers can achieve greater efficiency and quality in their production processes.

By leveraging these advancements, manufacturers can achieve greater efficiency and quality in their production processes.

Tips: Investing in adequate training for operators can lead to better utilization of fiber laser technology, ensuring skilled handling of the equipment. Regularly updating your systems and tools will help you stay competitive in the fast-evolving market of metal fabrication.

Speed and Efficiency Benefits of Fiber Laser Welders

Fiber laser welders have revolutionized the metal fabrication industry with their remarkable speed and efficiency. According to a recent industry report, fiber laser welding systems can operate at speeds up to five times faster than traditional welding methods. This significant increase in speed not only enhances productivity but also reduces production costs, allowing manufacturers to meet tight deadlines while maintaining high-quality standards. Moreover, fiber laser technology minimizes heat distortion, preserving the integrity of the materials being welded, which is essential for precision metal fabrication.

When it comes to complex geometries, fiber laser welders excel due to their ability to focus on a small area with extreme precision. This capability makes them ideal for intricate designs and delicate components, reducing the likelihood of errors and rework. A study highlighted that companies utilizing fiber laser welders reported a reduction in post-weld cleanup time by as much as 30%, which directly contributes to overall operational efficiency.

Tips: To maximize the benefits of fiber laser welding, ensure that your setup is optimized for the specific materials you are working with. Regular maintenance is crucial for sustaining performance and productivity. Additionally, investing in training for your operators can lead to improved usage of the technology, further enhancing the efficiency and accuracy of your fabrication processes.

Top 10 Fiber Laser Welder Benefits for Precision Metal Fabrication

| Benefit | Description |

|---|---|

| High Speed | Fiber lasers can cut and weld metal parts at significantly faster speeds than traditional welding methods. |

| Excellent Precision | The focused beam allows for high precision and the ability to create intricate designs with minimal distortion. |

| Versatility | Fiber lasers can work with various metals including stainless steel, aluminum, and copper. |

| Low Operating Costs | Higher efficiency leads to lower energy consumption, reducing overall operation costs. |

| Minimal Maintenance | Fiber laser systems require less maintenance compared to traditional welding tools, which helps reduce downtime. |

| Automation Ready | Easily integrates with automated systems allowing for streamlined production processes. |

| Reduced Heat Affected Zone | Results in less thermal distortion and higher integrity of the workpiece. |

| Portable Options | Many fiber laser welders are compact and portable, enabling flexibility in various work environments. |

| Environmentally Friendly | Produces less waste and uses less energy compared to traditional welding techniques. |

Cost-Effectiveness of Fiber Laser Welding in Manufacturing

Fiber laser welding has emerged as a transformative technology in the manufacturing industry, particularly due to its cost-effectiveness. Unlike traditional welding methods, fiber laser welding utilizes a concentrated beam of light to produce high-quality welds with minimal energy consumption. This efficiency not only reduces operational costs but also allows manufacturers to optimize their production processes. With the ability to weld a variety of metals quickly and precisely, businesses can enjoy lower labor costs and increased throughput, essential for maintaining a competitive edge.

Moreover, the longevity and low maintenance requirements associated with fiber laser systems contribute significantly to their cost-effectiveness. These systems are designed to operate without the need for extensive upkeep, which further minimizes expenses over time. Additionally, the precision of fiber laser welding results in less material waste and fewer defects, leading to savings in both raw materials and rework. By investing in fiber laser technology, manufacturers are not only enhancing their capabilities but are also aligning their operations with cost-saving strategies that can lead to significant improvements in their bottom line.

Versatility of Fiber Lasers in Various Metal Fabrication Applications

Fiber lasers have revolutionized the metal fabrication industry due to their remarkable versatility across various applications. Whether working with stainless steel, aluminum, or copper, fiber lasers provide exceptional precision and cutting speeds that are unmatched. This adaptability makes them suitable for projects ranging from intricate designs in jewelry making to robust structural components in automotive manufacturing. The ability to switch between different materials seamlessly allows manufacturers to optimize their production processes without compromising on quality.

Tip: When integrating fiber laser technology into your fabrication workflow, consider assessing the specific materials and thicknesses you'll be working with. This assessment will help you select the right settings for optimal performance, ensuring precision cuts and minimizing waste.

Another advantage of fiber lasers is their ability to handle complex shapes and designs with ease. This flexibility is essential for industries that require customized components, such as aerospace and electronics. Additionally, fiber lasers can operate at higher power levels, which not only enhances their cutting capabilities but also improves overall efficiency, reducing cycle times in production.

Tip: Regular maintenance of your fiber laser system can significantly extend its lifespan and maintain cutting accuracy. Schedule routine checks and cleaning to ensure that your equipment runs smoothly and produces consistent results.

Related Posts

-

Unlocking Precision and Efficiency with Handheld Laser Welders in Modern Manufacturing

-

Unveiling the Future: How Laser Welders Revolutionize Modern Manufacturing Techniques

-

Understanding the Benefits of Fiber Laser Welding Machines: A Comprehensive Guide for Modern Fabrication

-

Best Fiber Laser Welder Options for Precision and Efficiency in 2023

-

2025 Top Laser Marking Innovations for Enhanced Precision and Efficiency

-

Best Handheld Laser Welder for Precision and Portability in 2023