How to Effectively Use Laser Part Marking in Your Business?

In today’s competitive landscape, understanding how to effectively use laser part marking can set your business apart. As Mark Timmons, a renowned expert in the laser marking industry, states, “Precision and reliability are key in using laser part marking to enhance product identity.” This technology not only provides accuracy but also improves traceability in manufacturing.

Laser part marking involves using lasers to etch designs on various materials. It offers durability and resistance to wear over time. However, businesses must consider their specific needs and applications. Utilizing laser part marking effectively requires thoughtful planning and execution. Each mistake in this process can lead to costly errors.

Companies often overlook maintaining the equipment or misjudge the capabilities of laser part marking. Such oversights can result in production delays or subpar product quality. When businesses actively reflect on these challenges, they can harness the full potential of laser part marking. Embracing this technology can transform your operations, but it needs careful implementation and ongoing evaluation.

Understanding Laser Part Marking Technology

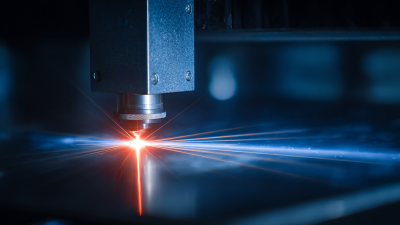

Laser part marking technology has transformed the manufacturing landscape. This method utilizes high-precision laser beams to create durable, clear markings on various materials. Reports show that industries using laser marking have experienced increases in efficiency by up to 30%. This technology is not just fast; it also minimizes product damage. The ability to mark intricate designs adds to its appeal.

Tips for effective implementation: Start by selecting the right laser type for your material. Fiber lasers work well with metals, while CO2 lasers suit plastics. Consider the depth and permanence of the markings based on your product needs. Regular maintenance of your laser equipment is crucial. It ensures consistent quality and reduces downtime.

However, adopting laser marking isn't without challenges. Initial costs can be high for some businesses. Training for staff is essential, as improper handling can lead to errors. Be prepared to adjust workflows to integrate this technology smoothly. By addressing these issues, businesses can better harness the potential of laser part marking. The investment will often bring long-term benefits.

Benefits of Incorporating Laser Marking in Your Business

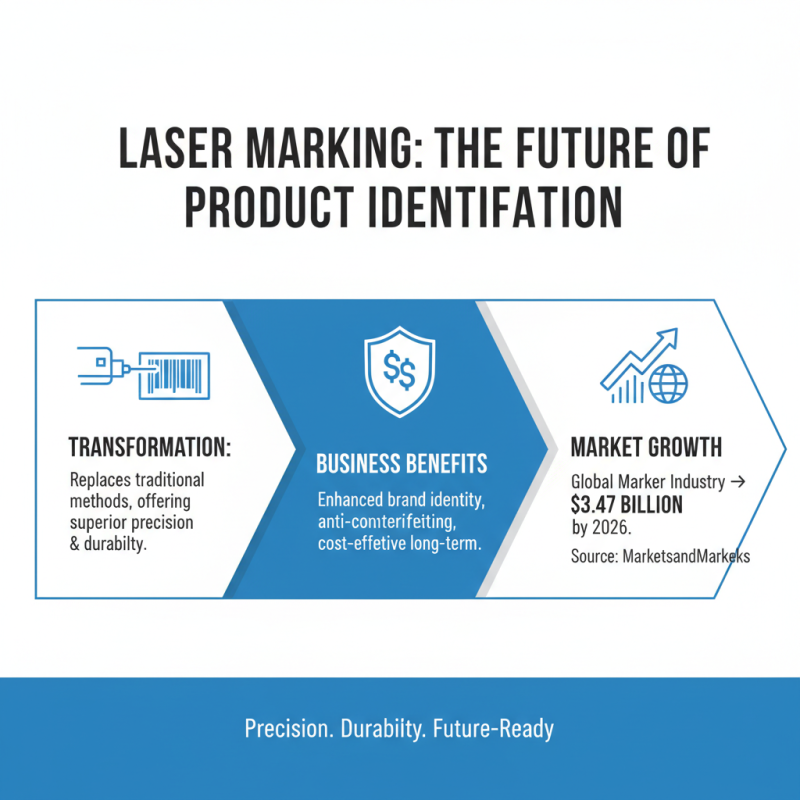

Laser marking has transformed how businesses identify and brand their products. Incorporating laser marking offers significant benefits. According to a recent report by MarketsandMarkets, the global marker industry is projected to reach $3.47 billion by 2026. This growth highlights the increasing reliance on precision and durability in product marking.

One major benefit of laser marking is its permanence. Unlike inks or labels, laser marks resist fading and wear. This longevity translates to lower maintenance costs. A study found that businesses can save up to 30% on re-marking expenses by using laser technology. Moreover, laser marking minimizes material waste. In some cases, businesses can achieve 90% less waste compared to traditional methods. However, initial investment and setup can be daunting. Companies must weigh these costs against long-term savings.

Another advantage is the versatility of laser marking. It works well on various materials, including metals, plastics, and glass. This adaptability allows businesses to customize their products easily. Yet, not all laser systems are equal. Choosing the wrong type can lead to inconsistent results. Regular training for staff is also crucial. Inconsistent usage can undermine the benefits of this technology.

Choosing the Right Laser Marking System for Your Needs

Choosing the right laser marking system is crucial for any business. Several factors come into play. You need to consider the materials you’ll be marking. Metals, plastics, and wood each require different types of lasers. Understanding these needs helps in selecting the best option.

Tips: Always analyze the compatibility of the laser with your product materials. A poorly matched system can lead to inefficient marking, or worse, damage to your items.

Think about the scale of your production. Are you marking small batches or large quantities? For high volume, faster systems may be necessary. However, smaller operations might afford more precise, but slower options. Reflecting on your workflow can save you from future bottlenecks.

Tips: Evaluate your production line. Make sure the chosen system integrates seamlessly. Disruption can lead to loss of valuable time and resources.

Lastly, consider the support and training available. New systems often require adjustments. If you're not equipped for that, it can slow down operations. A lack of understanding can hinder the benefits you aim to achieve with laser marking.

Implementing Laser Marking: Best Practices and Techniques

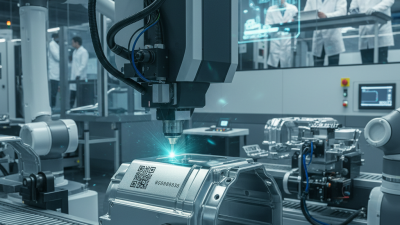

Laser marking has become essential in many industries. Businesses can achieve high precision and durability with this technology. However, implementing laser marking is not without challenges. Following best practices is crucial for success.

One key technique is material selection. Different materials react uniquely to laser marking. For example, metals can achieve deep etching, while plastics might melt. According to a recent industry report, over 70% of laser users experienced operational issues due to improper material choices. Testing materials before full-scale production can help prevent costly mistakes.

Another important aspect is equipment maintenance. Regular checks are vital to ensure accurate markings. Dirty lenses and misaligned components can lead to inconsistent results. Studies indicate that 60% of laser marking failures stem from insufficient maintenance practices. Training staff on proper equipment handling is also necessary. It’s a step that should not be overlooked. While laser marking offers many benefits, mistakes in implementation can tarnish a brand's reputation.

Maintaining and Troubleshooting Your Laser Marking Equipment

Maintaining and troubleshooting laser marking equipment is crucial for efficiency. According to industry research, improper maintenance can cause up to 30% of downtime in manufacturing processes. Regularly checking components can help mitigate this risk. Dust or debris can disrupt the laser beam. Keep the workspace clean and perform daily inspections.

Tips: Schedule regular maintenance. Have a checklist for every device. Ensure operators know the basics of troubleshooting.

If the machine shows inconsistent marking, it may need recalibration. Check the laser settings and ensure they align with the material specifications. Working with different substrates can introduce new variables. Pay attention to energy levels. Too low or too high may lead to quality issues.

Tips: Document any changes you make. Keep a log of settings for each type of material. This can help diagnose problems quickly.

Lastly, operator training is vital. Well-trained staff can spot issues early. A lack of knowledge can lead to costly mistakes. Regular training sessions can improve efficiency and reduce errors. Remember, mistakes are opportunities for learning. Evaluate and refine processes regularly.

Related Posts

-

Understanding the Benefits of Laser Marking Technology in Modern Manufacturing

-

2025 Top Laser Marking Innovations for Enhanced Precision and Efficiency

-

How to Effectively Use Laser Part Marking to Enhance Product Traceability by 70%

-

How to Choose the Best Laser Marking Systems for Your Business Needs

-

How to Choose the Right Part Marking Machine for Your Needs

-

2025 Guide: How to Choose the Best TIG Welding Machine for Your Needs