How to Choose the Best Laser Marking Systems for Your Business Needs

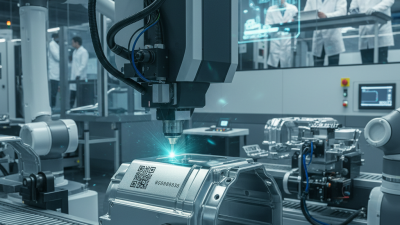

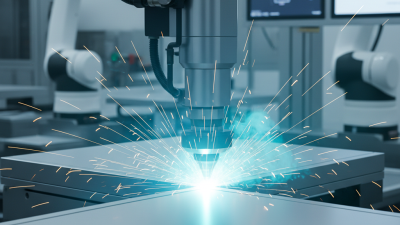

In today’s competitive manufacturing landscape, the selection of appropriate laser marking systems is crucial for businesses aiming to enhance product identification, traceability, and branding. According to a report by the International Laser Display Association, the global market for laser marking technologies is projected to grow at a CAGR of 6.5%, reflecting increasing demand across various sectors such as automotive, electronics, and pharmaceuticals. These systems offer versatility in marking materials, precision in design, and cost efficiency, positioning them as a vital asset for companies striving to meet both regulatory compliance and customer expectations.

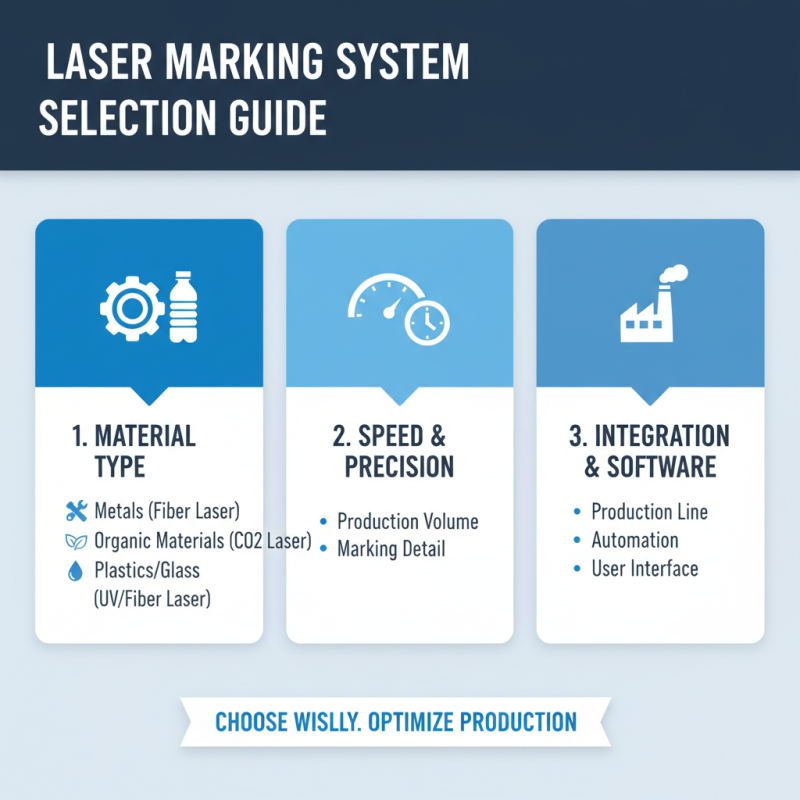

Selecting the right laser marking system involves understanding specific operational requirements and the diverse applications available. Factors such as the type of material to be marked, production speed, and the operational environment play significant roles in determining the most suitable system. The accuracy of laser marking enhances product authenticity and aids in effective supply chain management, as outlined in a recent market analysis by MarketsandMarkets. Integration of these advanced technologies not only streamlines manufacturing processes but also elevates brand value through improved quality assurance.

As businesses continue to adopt advanced manufacturing technologies, the importance of an informed choice in laser marking systems cannot be overstated. Understanding the various types of laser systems—such as fiber, CO2, and UV lasers—and their specific benefits enables businesses to implement solutions that best fit their unique needs, ultimately driving operational efficiency and enhancing market competitiveness.

Understanding the Different Types of Laser Marking Systems Available

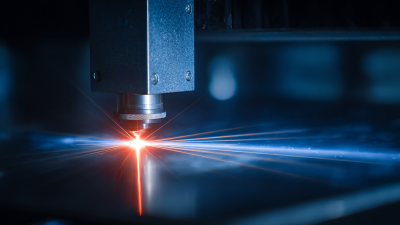

When selecting the best laser marking systems for your business, it's essential to understand the various types available, each designed for specific applications and materials. The most common types include CO2 lasers, fiber lasers, and UV lasers. CO2 lasers are ideal for marking organic materials like wood and plastic, while fiber lasers excel in engraving metals and high-contrast marking on various surfaces. UV lasers offer high precision for delicate materials, making them a favored option in the electronics and medical sectors.

Tips: Consider the materials you’ll be working with when choosing a laser marking system. For example, if your business focuses on plastic products, a CO2 laser might be the most suitable choice, while a fiber laser would be better for metal components. Additionally, think about the level of detail required in your markings; high-resolution tasks may benefit more from UV lasers due to their finer engraving capabilities.

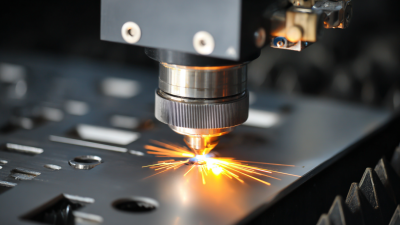

Another important factor is the scale of production. If your operations involve high volumes or fast-paced manufacturing, selecting a laser system with rapid marking speeds and minimal downtime should be a priority. Evaluating the maintenance needs and operational costs of each system is crucial to ensure long-term efficiency and productivity in your business.

Comparison of Different Types of Laser Marking Systems

Evaluating Key Features of Laser Marking Systems for Your Business

When selecting a laser marking system for your business, it's essential to evaluate the key features that directly align with your operational needs. First and foremost, consider the type of materials you will be working with. Different laser technologies, such as fiber, CO2, and UV lasers, offer varying capabilities depending on the material. Understanding whether you will mark metals, plastics, glass, or organic materials will help you choose a system that delivers high-quality results and avoids damaging your products.

Another critical aspect to consider is the speed and efficiency of the marking process. In a production environment, the ability of a laser system to keep pace with your output demands is crucial. Look for features such as advanced focusing optics and marking head designs that optimize speed without compromising on the quality of the markings. Additionally, assess the system's software capabilities, as user-friendly interfaces and support for various file formats can significantly enhance your workflow, reducing the learning curve for your team and ensuring seamless integration into your existing operations.

Assessing the Material Compatibility of Laser Marking Systems

When selecting a laser marking system for your business, one of the critical factors to consider is material compatibility. Different industries employ various materials, ranging from metals and plastics to ceramics and wood, each requiring specific laser wavelengths and technologies. According to a report by the Laser Institute of America, the most prevalent materials used in industrial applications for laser marking include stainless steel, aluminum, and polycarbonate, highlighting the necessity of choosing a system that can effectively mark or engrave these substrates.

For instance, CO2 lasers are particularly effective for non-metallic materials such as acrylic, paper, and wood, while fiber lasers excel at marking metals due to their shorter wavelength and higher peak power. Industry data shows that up to 40% of manufacturing processes rely on fiber lasers for speed and precision in marking metallic surfaces. Understanding the properties of the materials you intend to mark can significantly impact the laser system's performance and longevity. For example, marking on materials with reflective surfaces may require a specific approach to minimize the risk of energy reflection causing damage to the laser system.

Ultimately, assessing material compatibility not only ensures optimal marking quality but also enhances efficiency and cost-effectiveness in operations. The right laser marking system can lead to a substantial reduction in production downtime and maintenance costs, thus supporting a seamless integration into your existing manufacturing processes.

Cost Considerations: Budgeting for Laser Marking Systems Purchase

When budgeting for laser marking systems, it’s crucial to assess not only the initial purchase price but also the long-term operational costs. Start by evaluating the specific needs of your business, such as the type of materials you'll be marking and the production volume. These factors will influence the features you require, which in turn can affect the pricing of the systems available.

It’s essential to obtain quotes from multiple suppliers and consider any hidden costs, including installation, training, and maintenance.

Moreover, consider the efficiency and reliability of the systems you’re evaluating. A lower upfront cost may not always lead to savings if the machine has a higher rate of downtime or requires frequent repairs. Additionally, factor in the cost of consumables, such as replacement parts and any necessary software updates. Investing in a higher-quality system may come at a premium initially but can result in lower operational costs and increased productivity over time, making it a more economically sound choice in the long run.

Analyzing Supplier and Support Options for Laser Marking Systems

When considering laser marking systems for your business, analyzing supplier and support options is crucial. The primary factor to assess is the supplier's reputation and experience in the market. A supplier with a solid track record provides not only quality equipment but also insights on the latest technologies and advancements in laser marking. Look for suppliers who offer comprehensive background information, customer testimonials, and case studies that demonstrate their expertise in various industries.

Beyond the initial purchase, ongoing support and service play a vital role in ensuring the longevity and efficiency of the laser marking system. Evaluate the level of technical support provided, including availability of customer service representatives and the resources they offer for troubleshooting and maintenance. An effective support system should include training for your staff, quick response times for service requests, and access to spare parts. These factors contribute significantly to minimizing downtime and enhancing productivity in your operations. Selecting a supplier with strong support capabilities can help streamline your processes and ultimately lead to improved business outcomes.

Related Posts

-

Understanding the Benefits of Laser Marking Technology in Modern Manufacturing

-

2025 Top Laser Marking Innovations for Enhanced Precision and Efficiency

-

How to Effectively Use Laser Part Marking to Enhance Product Traceability by 70%

-

How to Master Laser Welding Aluminum Techniques for 2025

-

2025 Top 5 Argon Gas Products for Superior TIG Welding Performance

-

Top Features of the Best Laser Welding Guns for Precision Metalwork