How to Choose the Right Robotic Welding Systems for Your Business?

Choosing the right robotic welding systems for your business is crucial. The industry has shown significant growth, with a market size projected to reach $7.5 billion by 2025. Automation is reshaping manufacturing processes. Many companies are turning to robotic welding for precision and efficiency.

Expert Tom Anderson of Industry Robotics states, “Adopting robotic welding systems can enhance production rates while ensuring quality.” This highlights the importance of making informed choices. Companies may find options overwhelming. Balancing cost, technology, and application is essential. Each business has unique needs.

Selecting a suitable system requires careful evaluation. Factors like speed, accuracy, and compatibility with existing processes must be considered. While the benefits are clear, a misstep can lead to inefficiencies. Companies should conduct thorough research and engage with professionals. Making an informed decision helps avoid potential pitfalls and ensures long-term success in integrating robotic welding systems.

Understanding the Basics of Robotic Welding Systems

Robotic welding systems have transformed modern manufacturing. Understanding their basic functions can help businesses leverage their potential. These systems use programmable robots to perform welding tasks, offering precision and efficiency. They enhance productivity and reduce human error significantly.

Choosing the right system might feel overwhelming. Evaluate your specific needs first. Consider the types of materials, joint designs, and production volumes. Think about the space available for installation as well. A large robot may not fit into a small workshop. It’s crucial to tailor the choice to your business scale.

Tips:

Ensure your team receives training on operating and maintaining the system. Skilled workers can troubleshoot issues more effectively. Regular maintenance checks are vital to ensure optimal performance.

Also, reflect on your long-term production goals. Technology evolves quickly. What works today might need adjustments tomorrow. Being flexible in your approach allows for growth and adaptation in an ever-changing market.

Comparison of Robotic Welding System Features

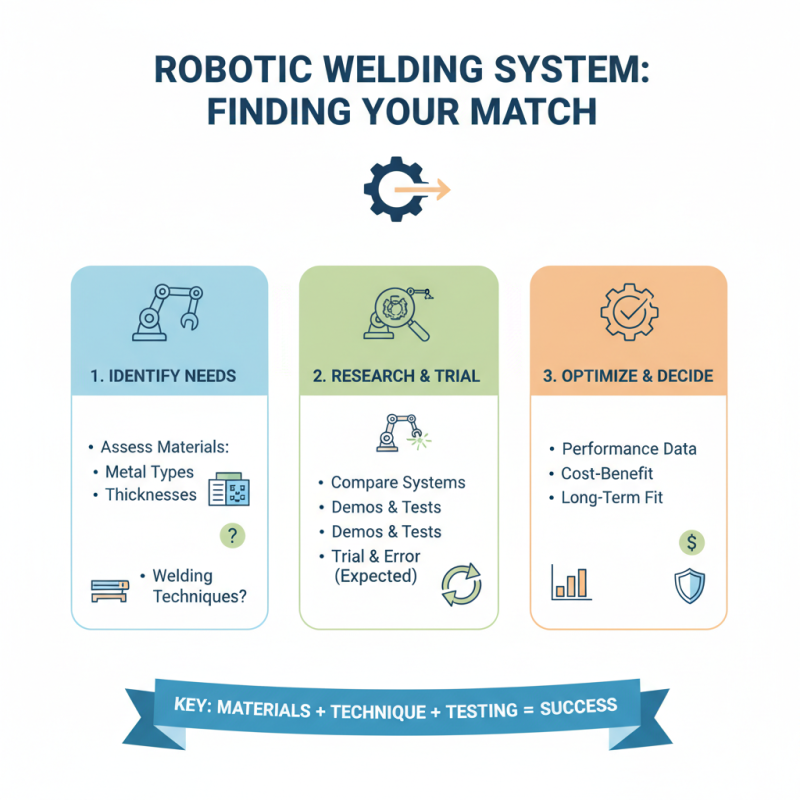

Identifying Your Business Needs and Requirements

Identifying your business needs is crucial for choosing the right robotic welding system. Start by assessing the types of materials you'll work with. Different metals and thicknesses require distinct welding techniques. It’s not always easy to predict which systems will perform best. Sometimes trial and error is necessary.

Consider your production volume. Will you need a system for high-volume production, or is a lower-output option sufficient? Higher performance systems can be costly. Weigh the benefits against your expected output. Also, think about space. Some systems require significant floor space. Is your facility ready for that?

Don’t forget to evaluate the skill level of your team. Training may be needed, but some systems are more user-friendly than others. It's a balancing act between usability and capability. Finally, keep maintenance costs in mind. A system might seem perfect, but hidden costs can sneak up on you. Be sure to plan for that.

Evaluating Different Types of Robotic Welding Technologies

When evaluating different types of robotic welding technologies, it's crucial to consider your specific needs. Each technology has distinct features and capabilities. For instance, some systems excel in precision, while others prioritize speed. Understanding these aspects can help in making a more informed decision.

Tips: Identify your production requirements early. Assess the materials you will be working with too. A system that works well with steel may not perform the same with aluminum.

Another important factor is the ease of integration. Some robotic welding systems may have a steep learning curve. This can disrupt workflow and increase downtime. Take the time to evaluate training and support options. It's worth considering how adaptable the system is to new processes.

Tips: Seek out user reviews. They can provide insights into the real-world performance of these systems. Don't overlook the importance of having a reliable support network.

How to Choose the Right Robotic Welding Systems for Your Business?

| Technology Type | Best Applications | Advantages | Disadvantages | Cost Range |

|---|---|---|---|---|

| MIG Welding Robots | Automotive, Heavy Machinery | Fast processing, Versatile | Less control on thin materials | $25,000 - $50,000 |

| TIG Welding Robots | Aerospace, Pipe Welding | High precision, Clean welds | Slower speed | $30,000 - $70,000 |

| Laser Welding Robots | Electronics, Medical Devices | Minimal heat distortion | High initial cost | $50,000 - $100,000 |

| Plasma Welding Robots | Construction, Shipbuilding | Good for thick materials | Not ideal for fine details | $20,000 - $40,000 |

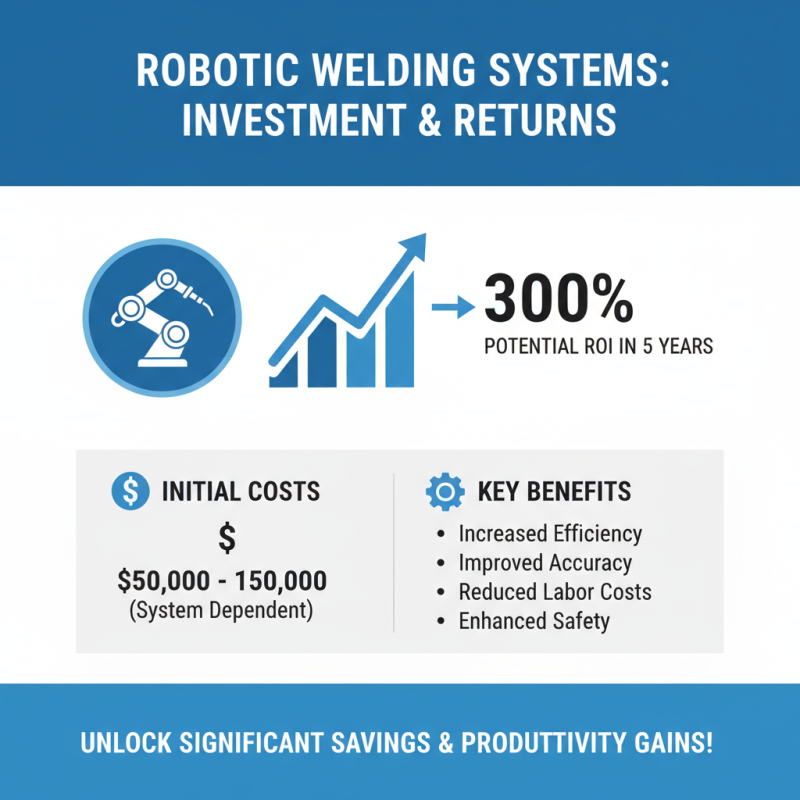

Comparing Costs and Return on Investment for Robotic Systems

Investing in robotic welding systems requires careful consideration of costs and potential returns. A recent report indicates that businesses can achieve a return on investment (ROI) of up to 300% within the first five years of implementation. This data presents compelling reasons for companies to explore these innovative solutions. However, the initial costs can be significant, often ranging from $50,000 to $150,000 depending on system specifications.

Upfront expenses are just the beginning. Maintenance, training, and integration should also be factored in. Many companies fail to account for these ongoing costs, which can reduce overall ROI. Some reports suggest that maintenance alone can account for 10-15% of total ownership costs annually. This could impact profitability if not managed effectively.

Another critical factor is productivity. Robotic systems can operate 24/7, offering a significant advantage over manual processes. Productivity increases of 30-50% are common, yet some organizations struggle to fully utilize their systems. They often underestimate the need for comprehensive training and change management to enhance efficiency. Understanding both the costs and the potential hurdles is essential for maximizing the benefits of robotic welding.

Assessing Supplier Reputation and Support Services for Integration

Choosing the right robotic welding system is crucial for business success. A key factor is supplier reputation. A report by the International Federation of Robotics indicates that 60% of companies consider supplier experience when making purchasing decisions. A reputable supplier often has a history of successful integrations. Reviews and industry ratings can provide insight into their reliability.

Support services are essential post-purchase. Many businesses overlook this aspect. A survey by Deloitte found that 45% of companies faced challenges during system integration. Proper training can mitigate these issues. Ensure the supplier offers comprehensive training programs and ongoing support. Ask about response times and availability for maintenance.

Consider the long-term implications of the supplier's support. A lack of timely assistance can lead to prolonged downtimes. This issue can cost businesses significantly. It's essential to weigh these factors when selecting a supplier. Reliability and support define a successful robotic welding integration. Take time to analyze all these elements carefully.

Related Posts

-

Exploring the Future: How Handheld Laser Welders Are Revolutionizing DIY Projects

-

Why Invest in a TIG Welding Machine for Your Next Project?

-

Unlocking Precision and Efficiency with Handheld Laser Welders in Modern Manufacturing

-

The Ultimate Guide to Tig Welding Gas Types and Their Uses

-

Top Features of the Best Laser Welding Guns for Precision Metalwork

-

10 Essential Tips for Choosing the Right MIG and TIG Welder for Your Projects