How to Choose the Right Part Marking Machine for Your Needs

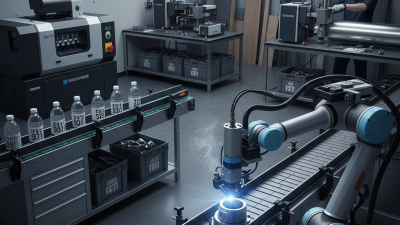

Choosing the right part marking machine is crucial for various industries. It impacts product identification and traceability. According to expert David Thompson, "The right machine not only marks but adds value to the production process." This insight underscores the importance of careful selection.

Part marking machines come in various types. Each serves different materials and applications. Factors like marking speed, durability, and technology are key. Businesses must assess their specific needs. A complex landscape exists, and navigating it can be challenging. Sometimes, less expensive options may lack longevity or precision.

Think about your production volume and product specifics. Understand the long-term implications of your choice. An inadequate machine can lead to increased costs over time. Reflect on your operational needs before making a decision. A thoughtful approach can yield significant benefits.

Identifying Your Part Marking Requirements and Objectives

Choosing the right part marking machine starts with understanding your specific needs. Different projects demand different marking methods. Identify what materials you are working with. Consider the size of the parts too. Each requirement will influence the type of machine that is suitable.

Tips: Evaluate the production volume. High volumes may need faster machines. Low volumes can work with simpler solutions.

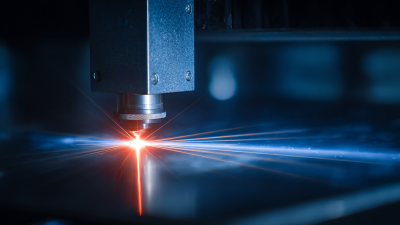

Think about the type of marking required. Is it permanent or temporary? Laser marking offers durability but may not be necessary for short-term applications. It's vital to have clarity on these aspects to avoid making an expensive mistake.

Tips: Test different marking methods before making a decision. Observe how each method affects your parts. Gather feedback from team members involved in the process.

Lastly, budget constraints will shape your options. Invest wisely, but avoid compromising quality for cost. Finding the right balance is crucial for long-term success in marking projects.

Exploring Different Types of Part Marking Technologies

When selecting a part marking machine, understanding the different marking technologies is essential. Marking methods vary based on the needs of your application. Common technologies include laser marking, dot peen marking, and inkjet marking. According to recent industry reports, laser marking offers precision and durability. It is suitable for various materials, including metals and plastics. Dot peen marking, on the other hand, excels in a more rugged environment. It delivers clear marks on uneven surfaces.

Choosing the right technology can be challenging. Each has its pros and cons. Laser machines are high-quality but often come with a higher price. Inkjet machines are versatile but may not last as long as other types. Your choice should depend on your specific requirements, material types, and production volume.

Tips: Always consider maintenance costs. Some machines require more upkeep, impacting your budget. Evaluate the material you'll be marking. Some technologies may perform better on certain surfaces. Testing different machines before finalizing is wise. Don’t skip this step, as it can save you from costly mistakes.

Evaluating Machine Specifications and Capabilities

Choosing the right part marking machine involves careful consideration of its specifications and capabilities. Different machines offer varied features. For instance, look for the type of marking method: laser, inkjet, or dot peen. Each has its strengths and limitations.

Speed and precision are vital. Consider the production volume you have. A slower machine may not meet your needs in a high-output environment. Always check the machine’s ability to handle different materials. Some machines work better on metals, while others excel with plastics.

Another important factor is maintenance. A complicated machine requires more time for upkeep. This can affect your overall efficiency. Ask about the learning curve. Some machines might need extensive training, which can slow down initial production. Reflect on these aspects carefully to avoid future challenges.

How to Choose the Right Part Marking Machine for Your Needs - Evaluating Machine Specifications and Capabilities

| Machine Type | Marking Technology | Max Marking Speed (items/min) | Material Compatibility | Power Consumption (W) | Price Range (USD) |

|---|---|---|---|---|---|

| Laser Marking Machine | Fiber Laser | 40 | Metal, Plastic | 300 | $8,000 - $15,000 |

| Dot Peen Marking Machine | Dot Peen | 60 | Metal, Hard Plastics | 150 | $5,000 - $12,000 |

| Ink Jet Marking Machine | Continuous Inkjet | 150 | Cardboard, Plastic | 100 | $4,000 - $10,000 |

| Electro Chemical Marking Machine | Electrochemical | 30 | Metal | 250 | $3,500 - $8,000 |

Considering Budget and Cost-Effectiveness in Machine Selection

When selecting a part marking machine, budget plays a critical role. Understanding your financial limits is essential. It's easy to get swayed by high-end options. However, these may not always offer the best return on investment. A machine might have fancy features but could be beyond your means. It's crucial to analyze whether these features are truly necessary for your operations.

Cost-effectiveness goes beyond the upfront price. Consider long-term expenses, including maintenance and consumables. A lower-priced machine may incur higher costs over time. Reflect on your production volume and how the machine will fit into your workflow. A machine that meets your immediate needs may not be optimal for future growth. This thought process helps avoid potential regrets later.

Gather details about warranty and support services as well. A good warranty can save costs in case of failures. But if service response is slow, this can disrupt your production. Balancing budget with reliability and capability is not straightforward. A well-rounded approach can lead to more informed and, yes, sometimes imperfect decisions.

Assessing Vendor Support and Maintenance Options

When selecting a part marking machine, vendor support is crucial. Look for companies that provide comprehensive support. This includes technical assistance and troubleshooting options. A strong vendor can make a significant difference if issues arise.

Tips: Ask potential vendors about their response times. Prompt support is vital. Also, inquire about training resources. Documentation and tutorials can ease the learning curve.

Maintenance options are another key aspect. Regular maintenance ensures longevity and reliability. Some vendors may offer maintenance contracts, which can be beneficial. Consider if these contracts suit your business needs.

Tips: Create a checklist of maintenance services offered. Assess how each aligns with your operation’s schedule. It’s important to reflect on whether self-maintenance is viable for your team. Every detail counts in your decision-making process.

Comparison of Part Marking Machine Features

Related Posts

-

Understanding the Benefits of Laser Marking Technology in Modern Manufacturing

-

2025 Guide: How to Choose the Best Marking Machine for Your Needs

-

The Ultimate Guide to Tig Welding Gas Types and Their Uses

-

Top 10 Handheld Laser Welding Machines for Efficient Metal Joining

-

Understanding the Benefits of Fiber Laser Welding Machines: A Comprehensive Guide for Modern Fabrication

-

Best Fiber Laser Welder Options for Precision and Efficiency in 2023