Best Fiber Laser Welder Options for Precision and Efficiency in 2023

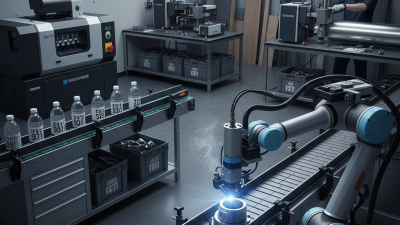

In the realm of modern manufacturing and fabrication, the demand for precision and efficiency has led to the remarkable rise of fiber laser welders. As we step into 2023, it becomes essential to explore the best fiber laser welder options that not only meet but exceed the standards of contemporary industrial requirements. Fiber laser welding technology is renowned for its unmatched speed, accuracy, and versatility, making it a game-changer for various applications, from automotive to aerospace, and even intricate artistic projects.

Choosing the right fiber laser welder can significantly influence production quality and operational efficiency. The advancements in this technology have transformed traditional welding practices, offering solutions that reduce thermal distortion and improve joint integrity. In this article, we will delve into an overview of the top fiber laser welder options available this year, highlighting their unique features and benefits. From compact models suitable for small-scale operations to robust systems designed for heavy-duty tasks, our exploration aims to equip manufacturers and hobbyists alike with the knowledge they need to select the ideal fiber laser welder for their specific needs.

Overview of Fiber Laser Welding Technology and Its Advantages

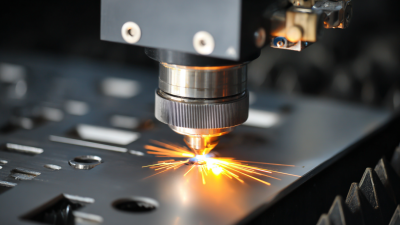

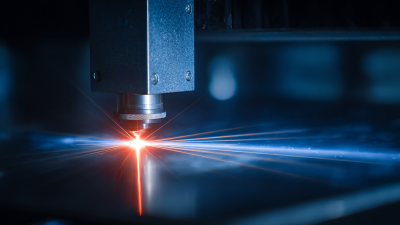

Fiber laser welding technology has revolutionized the metal fabrication industry, offering enhanced precision and efficiency for various applications. Utilizing a solid-state laser, fiber lasers produce a concentrated beam of light, which can be focused on a small spot, allowing for intricate and detailed welds. This high precision makes fiber laser welding suitable for welding thin materials, complex geometries, and applications requiring tight tolerances, thereby reducing the need for post-weld processing.

The advantages of fiber laser welding extend beyond just precision. The technology is also characterized by its speed and energy efficiency. Fiber lasers typically consume less power compared to traditional laser technologies, resulting in lower operational costs. Additionally, the rapid welding speeds allowed by fiber lasers improve productivity and throughput, making them an attractive option for manufacturers looking to optimize their production lines. Moreover, the minimal heat-affected zone reduces the risk of warping or distortion in the materials being welded, ensuring high-quality results in every application.

Key Features to Consider When Choosing a Fiber Laser Welder

When selecting a fiber laser welder, several key features should be carefully considered to ensure precision and efficiency. Firstly, the output power is critical; higher power levels generally lead to faster welding speeds and the ability to work with thicker materials. Welders with adjustable power settings allow for greater flexibility in handling diverse projects, from delicate jobs to heavy-duty applications.

Another important feature is the beam quality, often indicated by the focused spot size. A smaller, high-quality beam enables finer welds with minimal heat-affected zones, which is essential for intricate designs and thin materials. Additionally, consider the control systems available in the welder. Advanced systems may include programming settings and real-time feedback mechanisms, enhancing usability and precision.

Lastly, take into account the machine’s portability and weight, especially if the welder will be used in various locations or requires frequent transport. These considerations are vital in choosing the best fiber laser welder that meets both your operational needs and efficiency standards.

Top Fiber Laser Welder Brands and Models in 2023

In 2023, the fiber laser welding market has seen significant advancements, with various brands offering innovative models that cater to diverse industrial needs. Leading the pack is the Trumpf TruLaser series, renowned for its cutting-edge technology that provides high precision and efficiency. These machines come equipped with advanced beam quality and can handle materials of varying thickness with exceptional speed. Users appreciate the user-friendly interface, making it easy to operate even for those new to laser welding.

Another noteworthy contender is the Han's Laser range, which combines durability with top performance. The brand has made strides in integrating automation features, enhancing productivity while reducing the risk of human error. Their models often feature adaptive resonators that optimize power delivery based on the specifics of the job. Similarly, the IPG Photonics fiber lasers are making waves for their reliability and energy efficiency, ideal for businesses looking to reduce operational costs without sacrificing weld quality. As the demand for precision welding continues to grow, these top brands and their innovative models are setting the benchmark for excellence in the industry.

Best Fiber Laser Welder Options for Precision and Efficiency in 2023

Comparative Analysis of Performance and Efficiency in Fiber Laser Welders

In 2023, the market for fiber laser welders continues to impress with advancements in both precision and efficiency. A recent report by MarketsandMarkets indicates that the fiber laser market is projected to grow from $3.36 billion in 2022 to $6.17 billion by 2027, illustrating the accelerating adoption of this technology in various industries. This growth is largely driven by the increasing demand for efficient welding solutions that offer superior quality and reduced operational costs.

Comparative analysis shows that modern fiber laser welders excel in key performance metrics such as welding speed, energy consumption, and material versatility. For instance, according to a study conducted by the American Welding Society, fiber laser welders demonstrate a processing speed increase of over 50% compared to traditional welding methods. Additionally, their energy efficiency is noteworthy, often requiring up to 30% less power, which translates to significant savings over time. Manufacturers such as Trumpf and Amada are leading the way in developing advanced fiber laser systems, which not only improve productivity but also enhance the overall quality of welds, reducing the need for post-weld processing.

Best Fiber Laser Welder Options for Precision and Efficiency in 2023

| Model | Power (W) | Welding Speed (m/min) | Efficiency (%) | Weight (kg) |

|---|---|---|---|---|

| Model A | 1000 | 5.5 | 85 | 75 |

| Model B | 2000 | 7.0 | 90 | 100 |

| Model C | 3000 | 9.2 | 92 | 120 |

| Model D | 4000 | 10.0 | 95 | 150 |

| Model E | 5000 | 11.5 | 97 | 180 |

Tips for Maintenance and Optimal Use of Fiber Laser Welders

Maintaining fiber laser welders is crucial for achieving optimal performance and longevity. According to a report by MarketsandMarkets, the fiber laser market is expected to grow at a CAGR of approximately 10% between 2021 and 2026, highlighting the need for efficient operation and maintenance practices in the industry. Regular cleaning of the laser optics and work area helps ensure that the equipment remains free from contaminants, which can adversely affect the beam quality and welding precision.

In addition to cleaning, monitoring the cooling system is essential. A study by the International Journal of Advanced Manufacturing Technology indicates that improper cooling can lead to overheating, reducing the efficiency of the welding process and potentially damaging the laser source. Operators should also perform routine inspections to check for any signs of wear on components, as addressing minor issues can prevent larger, more costly repairs down the line. By adopting these maintenance tips, users can maximize the efficiency and precision of their fiber laser welders, thus enhancing their productivity in 2023 and beyond.

Related Posts

-

2025 Guide: How to Choose the Best Marking Machine for Your Needs

-

Exploring the Advantages of Hand Held Laser Welding Machines: Efficiency and Precision Unleashed

-

2025 Top Laser Marking Innovations for Enhanced Precision and Efficiency

-

Exploring the Future: How Handheld Laser Welders Are Revolutionizing DIY Projects

-

Understanding the Benefits of Laser Marking Technology in Modern Manufacturing

-

Unlocking the Future: How Micro Welders Are Revolutionizing Precision Manufacturing