Top 10 Benefits of Gas Tungsten Arc Welding You Need to Know

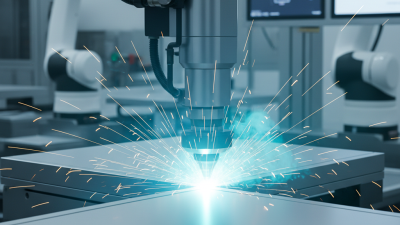

Gas tungsten arc welding (GTAW), often referred to as TIG (Tungsten Inert Gas) welding, is a sophisticated welding process that significantly benefits various industries, ranging from aerospace to automotive manufacturing. As noted by welding expert Dr. Mark Johnson, "The precision and control offered by gas tungsten arc welding make it the preferred choice for projects that demand exacting standards." This statement highlights the essential qualities of GTAW, including its ability to produce high-quality welds with minimal contamination.

The versatility of gas tungsten arc welding is another compelling advantage that should not be overlooked. Not only does it allow for the welding of a wide range of metals, including stainless steel, aluminum, and titanium, but it also offers the operator remarkable flexibility in adjusting parameters for different materials. Furthermore, the clean and efficient nature of GTAW minimizes the need for post-weld cleanup, enhancing productivity in various applications. In the following sections, we will explore the top ten benefits of gas tungsten arc welding that make it an invaluable technique in modern fabrication and repair work.

Advantages of Gas Tungsten Arc Welding in Various Industries

Gas Tungsten Arc Welding (GTAW) is widely recognized for its precision and versatility across various industries. One of the primary advantages of GTAW is its ability to produce high-quality welds with excellent control over the heat input, making it ideal for thin materials and intricate designs. This precision is particularly beneficial in sectors such as

aerospace and automotive manufacturing, where the integrity of welds is crucial for performance and safety. Moreover, GTAW generates minimal spatter, resulting in cleaner welds that often require less post-welding cleanup.

Another significant advantage of GTAW is its adaptability to different materials. Whether working with stainless steel, aluminum, or even exotic metals like titanium, GTAW provides consistent and reliable results. This flexibility makes it a favored choice in industries such as medical device manufacturing and food processing, where specific material properties must be maintained.

Tips for optimizing Gas Tungsten Arc Welding include maintaining consistent torch angles and travel speeds to achieve uniform penetration. Additionally, regularly checking and replacing tungsten electrodes can enhance performance, ensuring that welds remain strong and visually appealing. Lastly, ensuring a clean work surface before welding can significantly improve the quality of the final product.

Enhanced Precision and Quality of Welded Joints with GTAW

Gas Tungsten Arc Welding (GTAW), commonly known as TIG welding, is renowned for its enhanced precision and quality in the welding industry. This technique employs a non-consumable tungsten electrode to produce the weld, making it ideal for applications that demand high-quality finishes and minimal defects. According to the American Welding Society, GTAW provides one of the cleanest welds of any welding method, with a lower risk of contamination due to the inert shielding gas used during the process. This attribute not only increases the structural integrity of welded joints but also enhances their aesthetic appeal, appealing to sectors like aerospace and automotive manufacturing, where both strength and appearance are paramount.

To maximize the effectiveness of GTAW, it’s essential to consider some practical tips. First, ensure the workspace is free from contaminants that could affect the weld quality; any foreign material can lead to porosity and weaken the joint. Additionally, always use the appropriate filler material tailored to the base metals being welded, as improper filler can compromise the integrity of the weld. Lastly, maintaining a steady hand and consistent movement during welding will help achieve the desired bead size and appearance, further elevating the quality of the finished product.

Incorporating GTAW into your welding operations not only improves weld precision but also supports compliance with industry standards. Research by the International Institute of Welding indicates that the adoption of GTAW significantly reduces post-weld testing failures, driving down costs associated with rework and repairs. Thus, investing in GTAW technologies can lead to a more efficient production process while delivering high-quality results that satisfy stringent customer requirements.

Cost-Effectiveness and Efficiency of Using Gas Tungsten Arc Welding

Gas Tungsten Arc Welding (GTAW), commonly known as TIG welding, stands out for its cost-effectiveness and efficiency, making it a preferred choice for various industries.

One of the primary advantages of this welding method is its ability to produce high-quality welds with minimal defects. According to a 2022 industry report by the American Welding Society, TIG welding can achieve a defect rate as low as 0.5% in critical applications, significantly reducing rework costs and enhancing overall productivity. This precision is particularly beneficial in sectors requiring stringent quality standards, such as aerospace and medical device manufacturing.

Moreover, GTAW offers superior versatility compared to other welding processes. The technique can be used on a wide range of materials, including stainless steel, aluminum, and titanium. A report from the Fabricators & Manufacturers Association notes that the adaptability of TIG welding results in a 20% reduction in material waste, translating into substantial savings for manufacturers.

Additionally, the heat control provided by GTAW allows for thinner materials to be welded without distortion or burn-through, optimizing both resource utilization and production timelines. Ultimately, the economic efficiency of Gas Tungsten Arc Welding not only enhances operational budgetary performance but also contributes significantly to sustainable manufacturing practices.

Versatility of Materials Compatible with Gas Tungsten Arc Welding

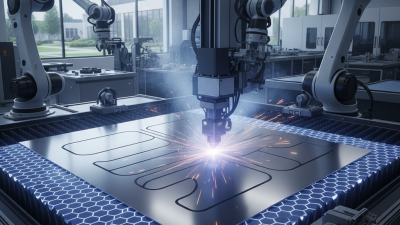

Gas Tungsten Arc Welding (GTAW), commonly known as TIG welding, stands out for its versatility in working with a wide range of materials. One of the defining characteristics of GTAW is its ability to weld both ferrous and non-ferrous metals effectively. This includes materials such as stainless steel, aluminum, copper, and titanium, making it an ideal choice for industries ranging from aerospace to automotive. The precision and control offered by GTAW allow welders to produce high-quality welds on thin sections of metal, minimizing the risk of distortion or warping.

Moreover, the versatility of GTAW extends beyond just metals. It can also be employed for welding various alloys, which often require specialized techniques to ensure strong joints. Utilizing a non-consumable electrode, GTAW creates a clean and stable arc that can be adjusted to suit different material thicknesses and types. This adaptability not only enhances the efficiency of welding operations but also broadens the scope of applications, from artistic metalwork to critical structural components in demanding environments. Such capabilities make gas tungsten arc welding a preferred choice for professionals seeking reliability and precision in their welding projects.

Safety Features and Environmental Benefits of GTAW Processes

Gas Tungsten Arc Welding (GTAW) is renowned not only for its precision but also for its emphasis on safety and environmental sustainability. One of the most significant safety features of GTAW is its low risk of fire and exposure to harmful fumes, which stems from its unique non-consumable tungsten electrode. According to the American Welding Society, GTAW produces less spatter compared to other welding methods, reducing the potential for thermal burns and improving operator safety. Additionally, the welder's ability to control the heat input minimizes warping and distortion, resulting in a cleaner and safer working environment.

From an environmental perspective, GTAW processes are notably cleaner than other welding techniques. The process results in minimal waste, as the electrode does not melt away, thus reducing the amount of material that needs to be disposed of. A study by the International Institute of Welding indicated that GTAW generates lower levels of emissions due to its efficient use of energy, making it an environmentally friendly choice for industries focused on sustainability. Moreover, the ability to use inert gases like argon and helium helps in minimizing hazardous fumes, contributing to a healthier workplace atmosphere.

Tip: To enhance safety while using GTAW, ensure that all operators are equipped with appropriate protective gear, including welding helmets with UV protection and gloves that can withstand high temperatures. Regular training on best practices can further mitigate risks associated with the welding process.

Related Posts

-

How to Master Laser Welding Aluminum Techniques for 2025

-

2025 Guide: How to Choose the Best Marking Machine for Your Needs

-

Mastering Tig Welding Aluminum Techniques for Stronger Joints and Improved Performance in Every Project

-

What is Aluminium Laser Cutting? Benefits, Process, and Applications Explained

-

Understanding the Benefits of Fiber Laser Welding Machines: A Comprehensive Guide for Modern Fabrication

-

Discover the Best Handheld Laser Welders for Top Efficiency in 2025