What is Aluminium Laser Cutting? Benefits, Process, and Applications Explained

Aluminium laser cutting has emerged as a transformative technology in modern manufacturing, offering precision and efficiency that traditional cutting methods cannot match. The global market for laser cutting systems is projected to reach $5 billion by 2025, driven by increased demand across various industries, such as automotive, aerospace, and consumer electronics. This growth is attributed to the rising adoption of aluminium components due to their lightweight and corrosion-resistant properties, making aluminium laser cutting a crucial process in contemporary fabrication.

Aluminium laser cutting has emerged as a transformative technology in modern manufacturing, offering precision and efficiency that traditional cutting methods cannot match. The global market for laser cutting systems is projected to reach $5 billion by 2025, driven by increased demand across various industries, such as automotive, aerospace, and consumer electronics. This growth is attributed to the rising adoption of aluminium components due to their lightweight and corrosion-resistant properties, making aluminium laser cutting a crucial process in contemporary fabrication.

According to Dr. James Lin, a leading expert in laser technologies, "Aluminium laser cutting not only enhances accuracy but also significantly reduces material waste, making it an eco-friendly choice for manufacturers." His insights highlight the dual benefits of precision machining and sustainability that this cutting technique offers. With the processing speed and quality improvements inherent in aluminium laser cutting, industries are increasingly recognizing its potential to create intricate designs and components that meet the rigorous demands of today's high-tech applications. As businesses continue to innovate, the role of aluminium laser cutting is set to expand, reshaping the landscape of industrial production.

Benefits of Aluminium Laser Cutting: Precision, Speed, and Cost-Effectiveness

Aluminium laser cutting has gained immense popularity due to its numerous advantages, notably precision, speed, and cost-effectiveness. This process utilizes a focused laser beam to cut through aluminium sheets with exceptional accuracy, minimizing the risk of material wastage. The precision offered by laser cutting is crucial in applications where tight tolerances are required, such as in the automotive and aerospace industries.

Speed is another significant benefit of aluminium laser cutting. Unlike traditional methods, which can take considerable time and labor, laser cutting machines can swiftly produce intricate designs and high volumes of parts. This efficiency not only enhances productivity but also allows manufacturers to meet urgent deadlines without compromising quality.

Tips: When considering aluminium laser cutting, ensure that the machine settings are optimized for the material thickness you are working with. Additionally, maintaining the laser optics will help in achieving the maximum cutting quality. It's also wise to evaluate the total cost of ownership by factoring in material usage and machine maintenance, which contributes to the overall cost-effectiveness of your production process.

Overview of the Aluminium Laser Cutting Process: Key Steps and Technologies

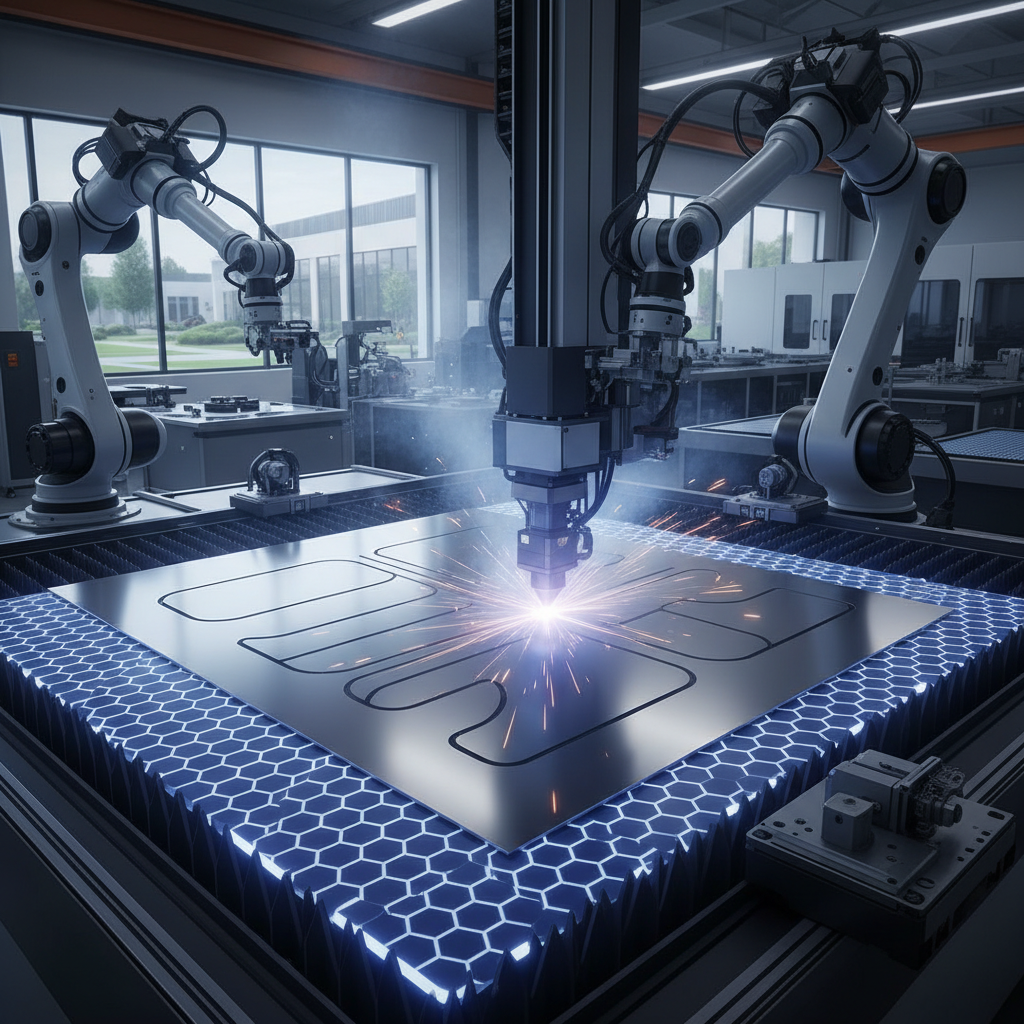

Aluminium laser cutting is a precise method used to cut various shapes and sizes from aluminium sheets and plates. The process begins with the preparation of the material, where the aluminium surface is cleaned to ensure optimal cutting quality. Once prepared, the aluminium sheet is placed on the cutting bed, with the design loaded into the laser cutting machine's software. This technology utilizes a high-powered laser beam, often derived from CO2 or fiber lasers, which is directed onto the aluminium surface to melt and vaporize the material along the preset paths.

During the cutting process, the laser beam not only provides extreme precision but also minimizes heat-affected zones, reducing the risk of distortions and ensuring clean edges. The key technologies involved include beam focusing systems, motion controls, and automated loading systems, which enhance the efficiency and accuracy of the cutting process. Post-processing options may also be applied, such as deburring or finishing, to achieve the desired surface quality. This advanced process is increasingly utilized across various industries, including automotive, aerospace, and construction, owing to its ability to deliver high-quality components with intricate designs.

What is Aluminium Laser Cutting? Benefits, Process, and Applications Explained

| Aspect | Details |

|---|---|

| Process Overview | Using laser technology to cut aluminium sheets with precision. |

| Key Technologies | CO2 lasers, Fiber lasers, and Nd:YAG lasers. |

| Benefits | High precision, minimal material waste, and ability to cut complex shapes. |

| Applications | Aerospace, automotive, electronics, and construction industries. |

| Material Thickness | Can effectively cut aluminium sheets up to 25mm thick depending on laser power. |

| Cost-Effectiveness | Lower operational costs compared to traditional cutting methods. |

Industry Applications of Aluminium Laser Cutting: From Automotive to Aerospace

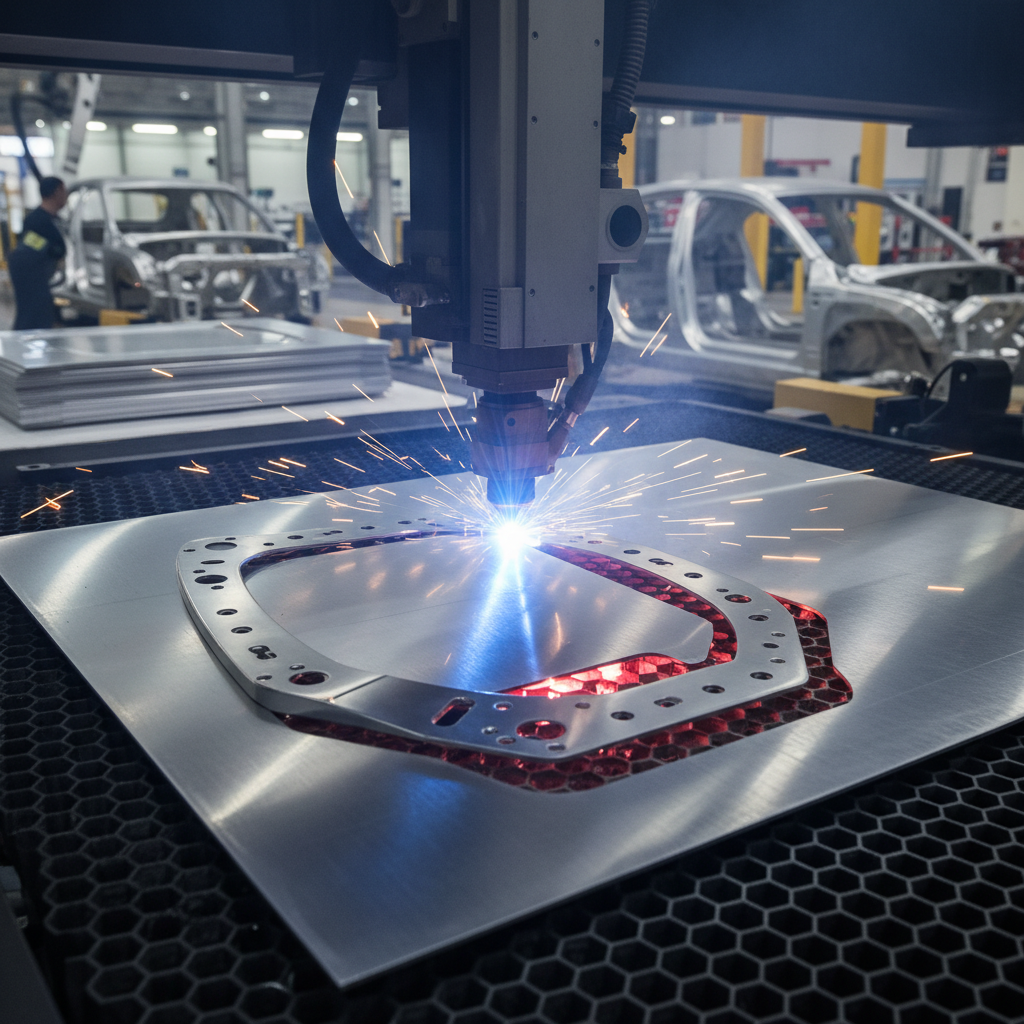

Aluminium laser cutting has become a pivotal technique across various industries due to its precision and efficiency. In the automotive sector, manufacturers utilize this technology to produce intricate components with tight tolerances, allowing for lightweight designs that enhance fuel efficiency. The ability to cut complex shapes quickly and accurately makes it ideal for producing parts such as brackets, trim pieces, and interior components, which require meticulous attention to detail.

In the aerospace industry, the application of aluminium laser cutting extends to the fabrication of structural components and components for aircraft interiors. The lightweight nature of aluminium combined with laser cutting's versatility enables manufacturers to create components that improve overall aircraft performance and reduce operational costs. The demand for lightweight, high-strength materials in aerospace further drives the adoption of aluminium laser cutting technologies, making it a game-changer in both manufacturing and safety in modern aviation.

Trends in Aluminium Laser Cutting: Market Growth and Technological Advancements

The aluminium laser cutting industry is experiencing significant growth, driven by advancements in technology and an increasing demand across various sectors. With rising needs in the automotive and aerospace industries, companies are investing in cutting-edge laser cutting equipment that enhances precision and efficiency. The shift towards automation and CNC processing techniques has also contributed to the rapid expansion of the market, with manufacturers focusing on optimizing their cutting processes to achieve better quality and faster turnarounds.

Trends indicate a strong movement towards environmentally sustainable practices, prompting the adoption of new laser technologies that minimize waste and energy consumption. The market is also diversifying based on material types, with aluminium becoming a prominent focus due to its lightweight properties and versatility. As end-user industries continue to evolve, suppliers are adapting their product offerings, leading to a competitive landscape where innovation plays a vital role in meeting specific application needs. This ongoing development is expected to shape the future of aluminium laser cutting, positioning it as a crucial component within the broader metal processing equipment market.

Comparative Analysis: Aluminium Laser Cutting vs. Traditional Cutting Methods

Aluminium laser cutting has gained popularity due to its precision and efficiency, especially when compared to traditional cutting methods like plasma or mechanical cutting. The laser cutting process utilizes a focused beam of light to melt or vaporize the material, providing clean edges and reducing the need for secondary processing. Traditional methods, while effective, often lead to larger heat-affected zones, greater material distortion, and a rougher finish. This comparative analysis highlights how aluminium laser cutting minimizes these drawbacks, resulting in superior surface quality and dimensional accuracy.

In addition, technologies such as femtosecond laser ablation demonstrate advancements in the laser cutting realm by offering even more focused energy delivery, leading to highly efficient and precise cutting. Unlike traditional plasma cutting, which can introduce significant heat into the material, this ultrafast processing method preserves the integrity of aluminum, rendering it ideal for applications requiring intricate designs. Ultimately, the shift toward laser technologies signifies a broader trend towards more sustainable and effective manufacturing practices across various industries.

Related Posts

-

Understanding the Benefits of Fiber Laser Welding Machines: A Comprehensive Guide for Modern Fabrication

-

2025 Top 5 Argon Gas Products for Superior TIG Welding Performance

-

Exploring the Future: How Handheld Laser Welders Are Revolutionizing DIY Projects

-

Understanding the Benefits of Laser Marking Technology in Modern Manufacturing

-

Mastering Tig Welding Aluminum Techniques for Stronger Joints and Improved Performance in Every Project

-

Unlocking the Future: How Micro Welders Are Revolutionizing Precision Manufacturing