2025 Guide: How to Choose the Best Marking Machine for Your Needs

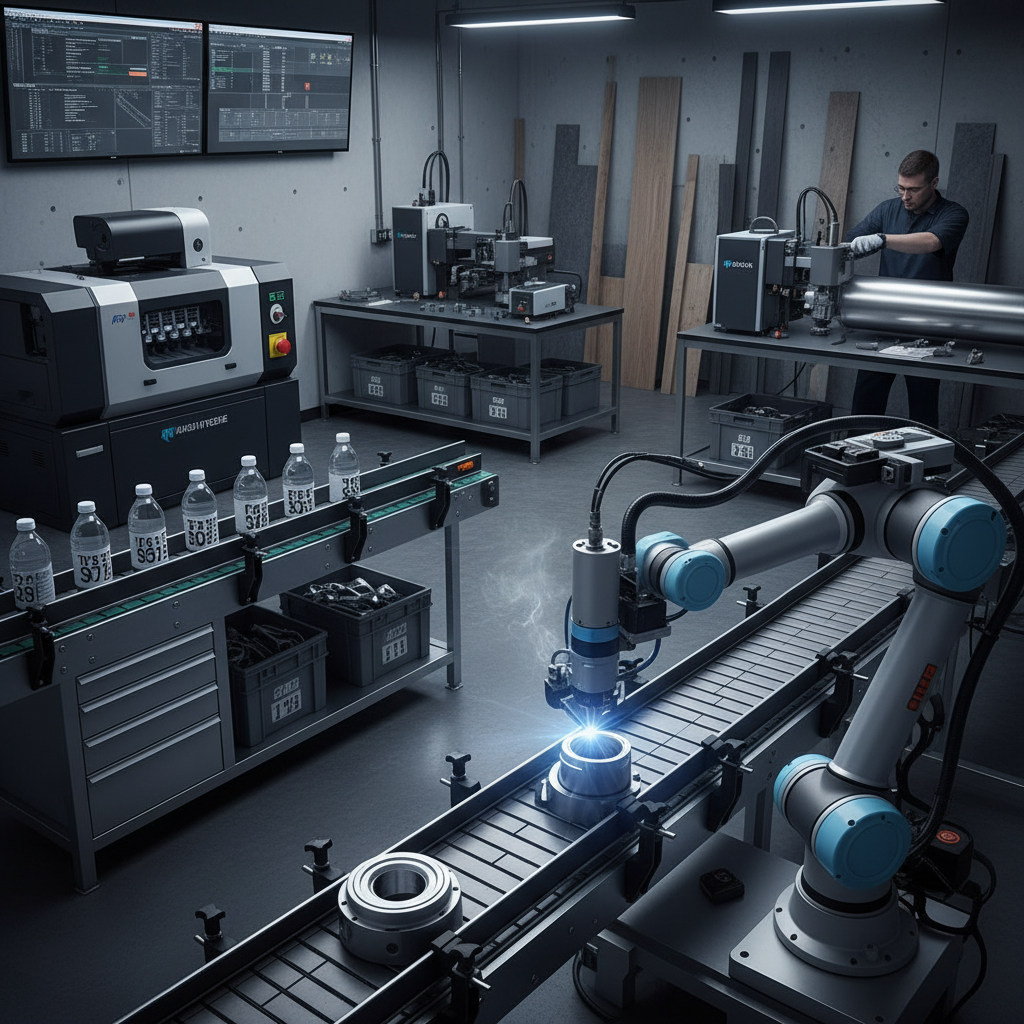

In an increasingly competitive manufacturing landscape, the choice of the right marking machine can have a significant impact on both product quality and operational efficiency. As businesses strive to meet consumer demands for traceability and compliance, understanding the various types of marking machines available in 2025 is essential. From laser engravers to inkjet printers, each marking machine comes with its unique features and capabilities, designed to cater to different materials, sizes, and production speeds.

Selecting the ideal marking machine is not just about picking the latest technology; it involves evaluating your specific needs, including the types of materials you'll be marking, the desired permanence of the marks, and the environments in which the machines will operate. Additionally, considerations such as budget constraints, maintenance requirements, and available support services play a crucial role in this decision-making process. This guide will provide insights into these factors, ensuring you can make an informed choice that aligns with your operational goals and production requirements.

Understanding Different Types of Marking Machines Available in 2025

In 2025, the landscape of marking machines offers a variety of options tailored to diverse industrial needs. From laser and dot peen to mechanical and inkjet marking systems, each type presents unique advantages and capabilities. According to a recent market analysis by Credence Research, the global marking machine market is projected to reach USD 4.2 billion by 2025, driven by advancements in technology and increased demand for product traceability across sectors such as aerospace, automotive, and consumer goods.

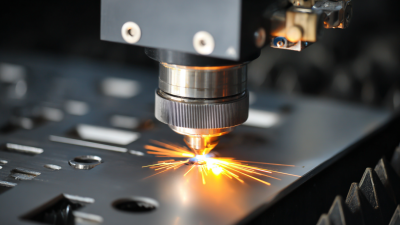

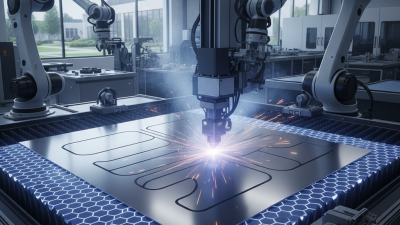

When selecting the right marking machine, consider the materials you'll be working with. Laser marking machines, known for their precision and permanence, are ideal for metals and plastics, while inkjet systems are suitable for porous surfaces like cardboard and wood. A 2023 report from Grand View Research highlighted that over 30% of manufacturers prefer laser systems due to their efficiency and ability to perform intricate designs without inks or solvents.

Tips: Always assess the required marking speed and volume to ensure the machine you choose aligns with your production needs. Additionally, look for machines with user-friendly software that facilitate easy programming and operation. This can enhance workflow and minimize downtime across your operations.

Key Factors to Consider When Selecting a Marking Machine

When selecting a marking machine that best suits your needs, several key factors should be taken into account. Firstly, you need to consider the type of materials you will be marking. Different marking machines, such as fiber laser, diode laser, solid-state laser, CO2 laser, and UV laser, each have their own strengths and weaknesses depending on the material type. For example, fiber lasers are ideal for metals, while CO2 lasers perform exceptionally well on wood and plastics.

Tips: Always assess your primary application and the materials involved when choosing a product type. Additionally, evaluate the required marking speed and precision. An efficient marking machine not only enhances productivity but also reduces operational costs in the long run.

Furthermore, consider the machine's maintenance requirements and ease of operation. Machines that offer user-friendly interfaces and require minimal downtime for maintenance will be easier to manage in a busy production environment. Reviewing customer feedback and product reviews can provide insights into the reliability and performance of different marking machines, ultimately aiding in your decision-making process.

2025 Guide: How to Choose the Best Marking Machine for Your Needs - Key Factors to Consider When Selecting a Marking Machine

| Feature | Description | Importance |

|---|---|---|

| Marking Technology | Types include laser, dot peen, inkjet, etc. | High |

| Material Compatibility | Suitable for different materials: metals, plastics, etc. | High |

| Speed | How quickly the machine can mark items. | Medium |

| Portability | Ease of moving the machine for on-site marking. | Medium |

| Software Ease of Use | User interface and functionality of the marking software. | High |

| Maintenance Requirements | Frequency and complexity of maintenance needed. | Medium |

| Budget | Overall cost including purchase, setup, and operation. | High |

| Power Requirements | Voltage and power needs for operation. | Low |

| Customer Support | Quality of technical support and after-sales service. | High |

Assessing Your Specific Marking Needs and Applications

When selecting the best marking machine for your needs, it is crucial to assess your specific marking requirements and applications. Start by identifying the materials you will be working with, such as metal, plastic, or wood, as different machines are designed to handle various substrates. Additionally, consider the size and shape of the items to be marked; larger or irregularly shaped pieces may require specialized equipment to ensure clear and accurate markings.

Next, evaluate the type of marking you intend to perform. Options range from engraving and laser marking to inkjet printing and dot peening. Each method has its advantages depending on factors like durability, speed, and precision. If your application demands high-speed production, for example, a reliable inkjet marking machine might be ideal. However, if traceability and permanent marking are paramount, a laser marking machine could be the better choice. Taking the time to thoroughly assess these factors will ensure you choose the marking machine that best meets your operational needs.

Budget Considerations: Cost vs. Features of Marking Machines

When selecting a marking machine, budget considerations play a crucial role in balancing cost against features. According to a report by MarketsandMarkets, the global industrial marking systems market is expected to reach $4.8 billion by 2025, indicating a growing demand for advanced marking solutions. In this competitive landscape, understanding the correlation between a machine's cost and its features can significantly impact your investment decision.

High-end marking machines often come with advanced capabilities such as high-speed laser marking, integrated software solutions, and enhanced durability, which can justify a higher price tag. For instance, a laser marking machine can range from $5,000 to over $100,000, depending on its specifications. While a lower-cost option may seem appealing, it might lack essential features, such as precision or compatibility with various materials, leading to increased operational costs over time. Therefore, evaluating both initial purchase prices and long-term operational efficiency is vital for making an informed choice that aligns with your specific marking needs.

2025 Guide: Marking Machine Cost vs. Features

Maintenance and Support: Ensuring Longevity of Your Machine

When selecting a marking machine, understanding the importance of maintenance and support can significantly extend its longevity and reliability. Predictive maintenance solutions can provide you with valuable insights into your machinery's performance, enabling you to preemptively address issues before they lead to costly downtimes. This approach not only enhances operational efficiency but also ensures that your marking equipment remains in peak condition.

In addition, comprehensive support programs can further safeguard your investment. Scheduled service and regular check-ups are essential to maintaining optimal performance. Engaging with providers that offer robust maintenance services and expert consultations can help ensure that your marking machines operate reliably over the years. Proactive measures in maintenance not only extend the lifespan of your equipment but also contribute to a more predictable and manageable workflow in your operations.

Related Posts

-

2025 Top Laser Marking Innovations for Enhanced Precision and Efficiency

-

Revolutionizing Manufacturing: How Welding Automation Increases Efficiency by 30% and Reduces Costs

-

What is Aluminium Laser Cutting? Benefits, Process, and Applications Explained

-

Exploring the Future: How Handheld Laser Welders Are Revolutionizing DIY Projects

-

Unlocking the Secrets: MIG vs. TIG Welder - Which Welding Technique Reigns Supreme?

-

Unlocking the Future: How Micro Welders Are Revolutionizing Precision Manufacturing